Increased Service Life and Cost Savings

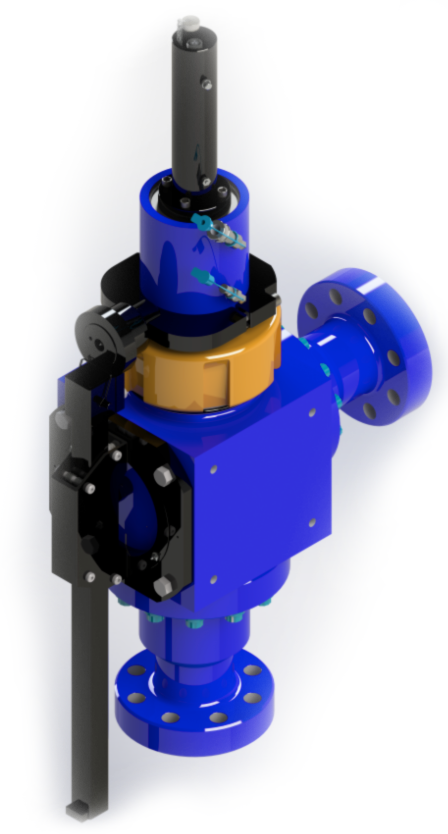

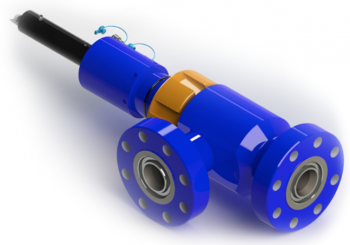

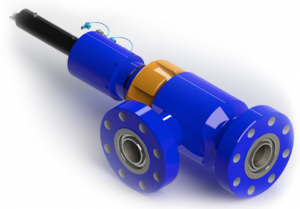

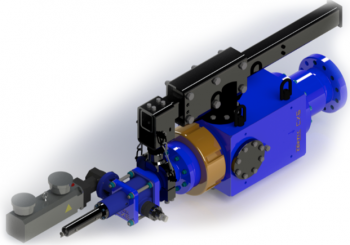

CORTEC Drilling/Extreme Service Chokes are designed to offer the oilfield operator increased service life and cost savings in high-pressure applications where substantial amounts of solids and abrasives are present. Models are designed for extreme conditions like frac flowback, drilling, choke & kill, coil tubing, well control and snubbing. Models Available in this line include: CX-3 (Hydraulic Piston & Worm Gear), CXC2 and CX-6.

|

|

|

|

CORTEC Model CX3 |

CORTEC MODEL CX3 |

CORTEC Model CXC2 |

CORTEC Model CX-6 |

Features & Benefits |

Choke Models |

|||

|---|---|---|---|---|

|

CX3 Worm Gear |

CX3 Hydraulic Piston |

CXC2 |

CX-6 |

|

| Manufactured to API-6A PSL-3 | X | X | X | X |

| Manufactured to NACE MR0175 | X | X | X | X |

| API-16C monogram available upon request | X | X | X | * |

| Available in 1-1/2″ or 2″ orifice size | X | X | X | |

| Available in 3″ orifice size | X | X | ||

| Available in 6″ orifice size | X | |||

| Available up to 15,000 PSI | X | X | X | |

| Available up to 5,000 PSI | X | |||

| SS RTJ weld overlay on inlet/outlet grooves as a standard | X | X | X | |

| Tungsten carbide reversible trim set | X | X | X | |

| Gantry system available upon request | X | X | X | |

| Wear-resistant nose cone for extended wear protection (intergral with bonnet on CXC2) | X | X | X | X |

| Tungsten carbide wear sleeves installed in outlet spool for extended wear protection (only 1 sleeve in CXC2) | X | X | X | X |

| Electric control options available upon request | X | X | ||

| Manual override capability | X | X | ||

| Digital position indicator | X | X | X | X |

| Gate, seat, stem and bonnet removal tools available upon request | X | X | X | X |

* Consult Factory for Details