Attention to Every Detail

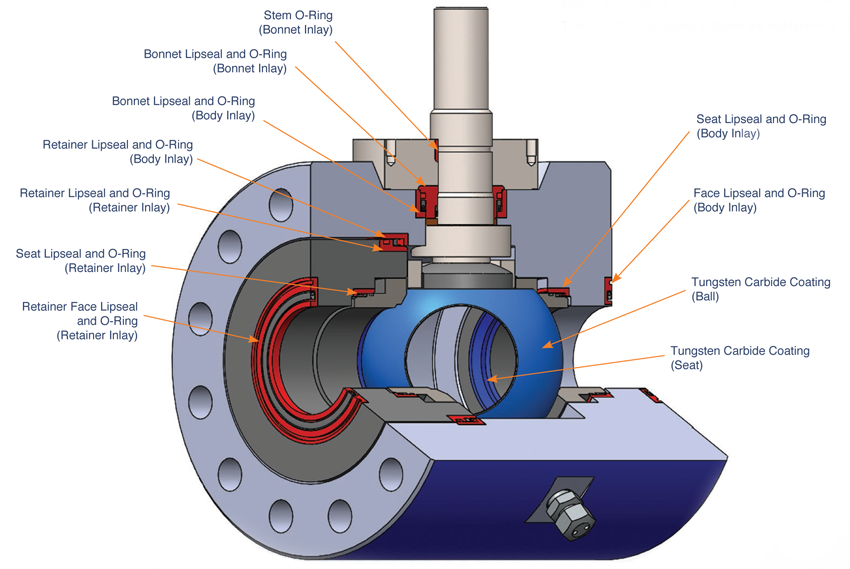

Typical Critical Service Design – Inconel 625 Inlay for seal areas are highlighted in RED Tungsten Carbide coated surfaces are highlighted in BLUE.

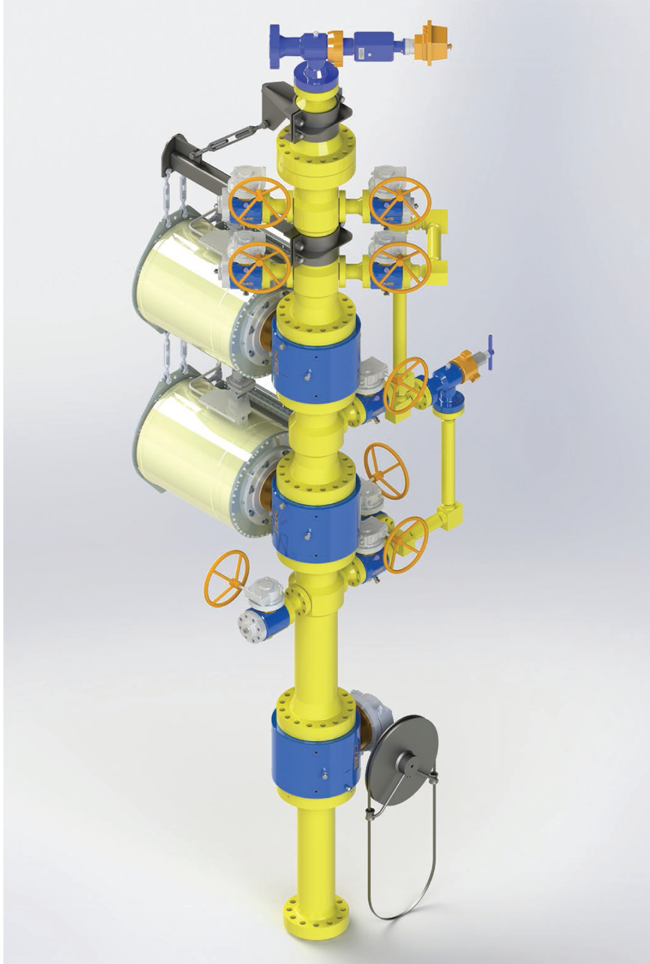

CORTEC BSDV Valves

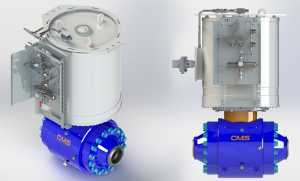

CORTEC BSDV valves are designed and tested to meet the requirements of 30 CFR 250, Subpart H which is required by BSEE for riser applications in the US Gulf of Mexico. All BSDV’s are manufactured under an API Q1 quality system, and shipped with documentation that certifies API 6A and API 6AV1 Class II (Sand Slurry Tested) compliance as well as API 6FA fire rated.

For valves used in critical applications such as BSDVs (Boarding Shutdown Valves), CORTEC’s metal seated valves are designed to function in the most extreme conditions to which they may be exposed. This includes temperature, pressure, flow rates with abrasives and other adverse conditions. In addition, BSDVs are manufactured using materials and sealing elements that are designed to last for the life of the well.

For long term operability, attention is given to all sealing areas, not just the bore sealing mechanism (seat to ball seal). For this reason, CORTEC has developed the “LD” Series Ball Valve. This valve uses specially designed spring energized lipseals in all primary sealing elements.

Special attention has been given to the design of these lipseals to ensure reliable sealing from very low pressures to full rated working pressure. Additionally the materials used in sealing gland areas are selected for long term reliable sealing.

CORTEC’s designs include provisions for Inconel 625 overlays, in accordance with API 6A, to greatly improve sealing reliability and longevity in all areas of the valve. Please consult with your CORTEC representative for additional information.