CORTEC believes that nothing is more important than safe, reliable product performance.

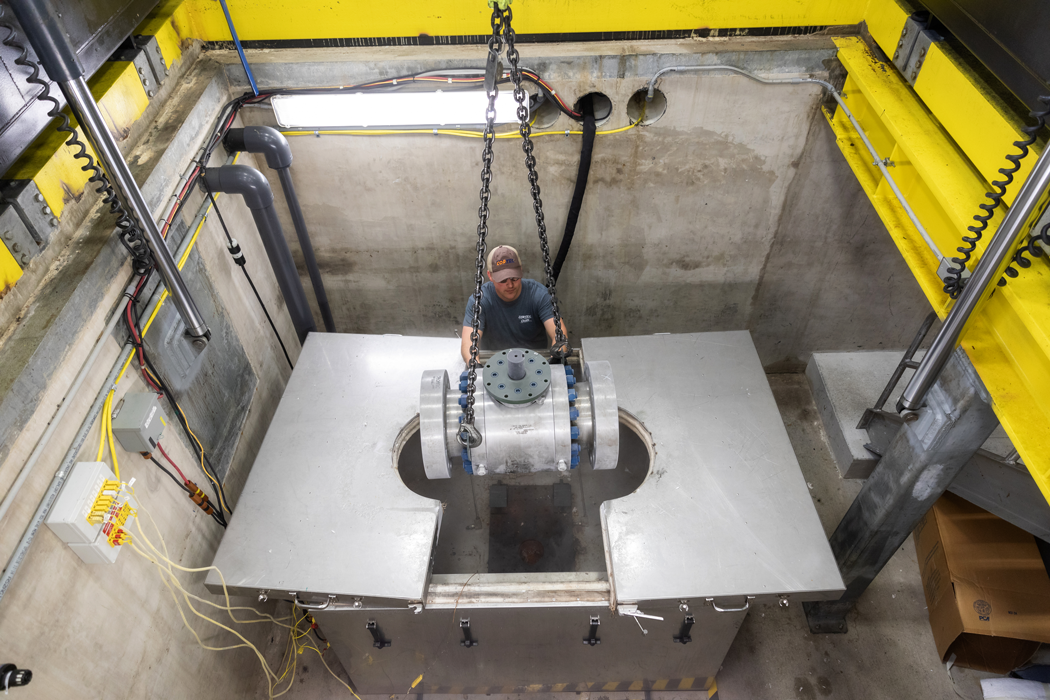

Our experienced team is fully equipped with the tools to perform extensive testing on model prototypes, which ensure the design processes and analytical verifications result in a proven, validated product.

CORTEC. Crafted for Confidence.

During testing, all our products are subjected to extreme conditions that push them well beyond their expected operating limits. Only by subjecting them to a battery of rigorous testing can we ensure our valve models will thrive in the most punishing in-service environments — when it matters most.

With our comprehensive in-house testing capabilities, we are able to ensure that our products are durable to the extreme, meeting and exceeding industry standards and requirements every step of the way.

Safety and reliability are at the forefront of every product we manufacture and project we supply. As a result, CORTEC is an active participant on several API standard committees, working alongside our peers to advance the reliability and safety in the industry.

Learn More Our Testing Capabilities

Set Up a Meeting With CORTEC

UPDATES & EXPERIENCE

CORTEC Receives “SIL” Certification for CRV Pressure Relief Valve and Trunnion Ball Valve

CORTEC Receives “SIL” Certification for CRV Pressure Relief Valve and Trunnion Ball Valve

CORTEC has received a Safety Integrity Level (SIL) certification on its Model Series “CRV” Pressure Relief Valves and Model Series “D” and “LD” Trunnion Ball Valves, which verify the safety of the products.

The SIL certification provides a quantification of the reduced likelihood of a hazardous event from occurring and assures that an independent third party reviewed the safety of the design and function of the product. READ THE FULL STORY

CORTEC Awarded Shell Vito Valve Packages

CORTEC Awarded Shell Vito Valve Packages

CORTEC has been contracted to supply multiple valve packages for the Vito project including API 6AV1 rated Boarding Shutdown Valves. Positioned in the Mississippi Canyon block of the Gulf of Mexico, this system will feature models ranging from 2-1/16” to 10-1/8” bore and pressure classes up to 15,000 PSI. These packages include both Peek and Tungsten Carbide metal to metal seated designs.

CORTEC continues to redefine the market with innovative ball valve designs that minimize weight and space requirements while maximizing performance. These designs save valuable deck space while reducing piping manifold designs by several tons when compared to conventional gate and ball designs. Fully compliant with API 6A and 6AV1 standards, CORTEC’s designs are independently third-party tested offering improvements in function and service life. READ THE FULL STORY