CORTEC Products are Built for the Pressure

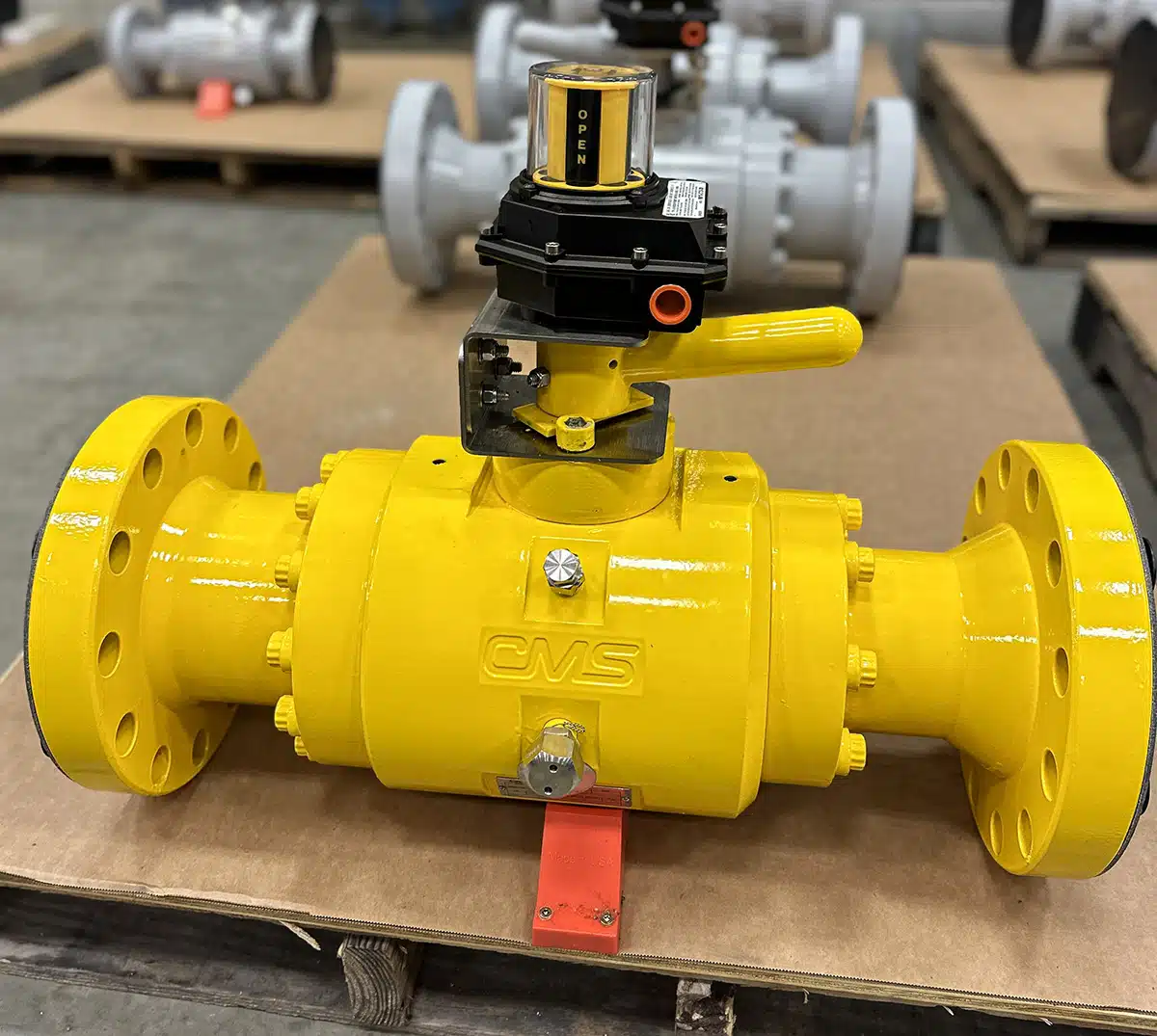

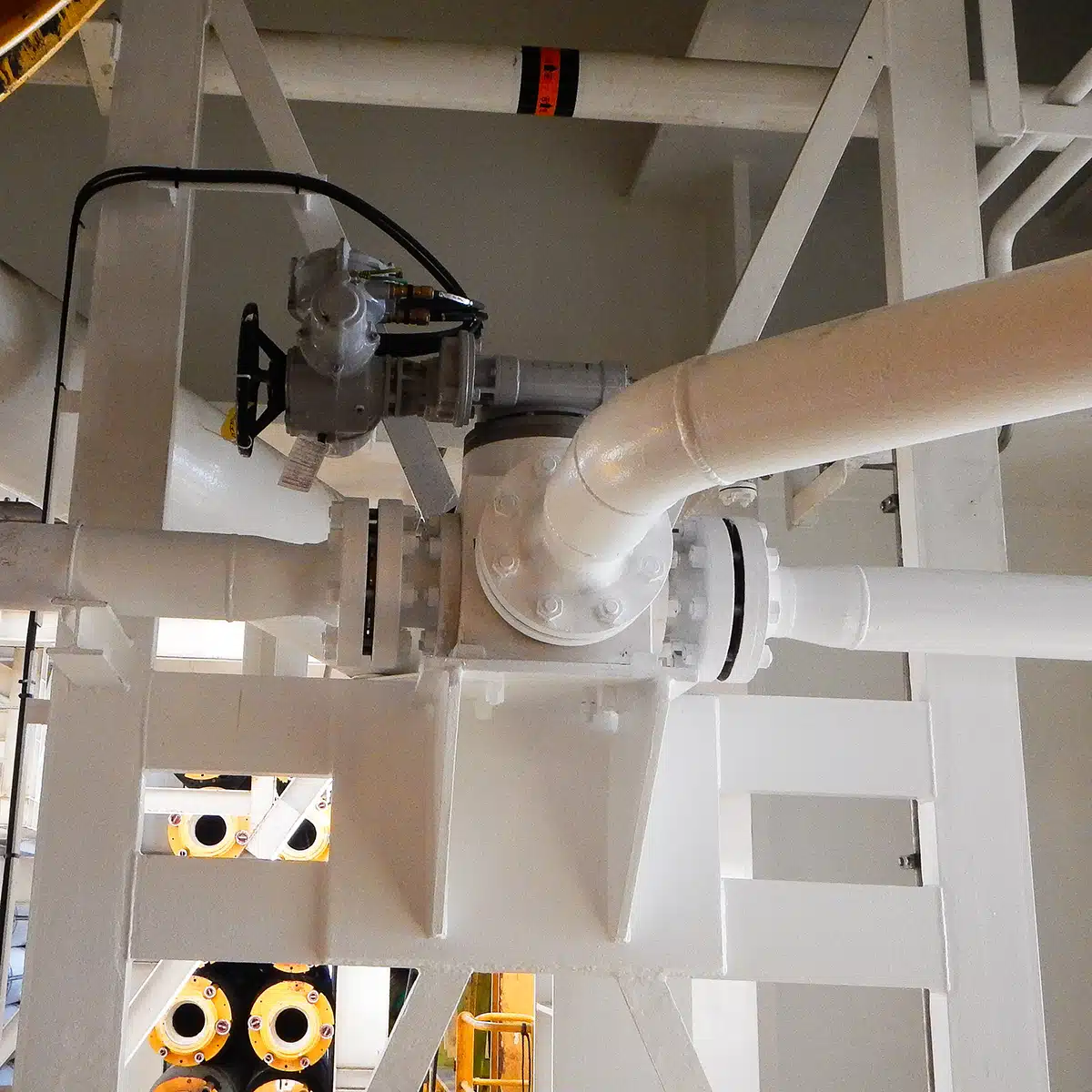

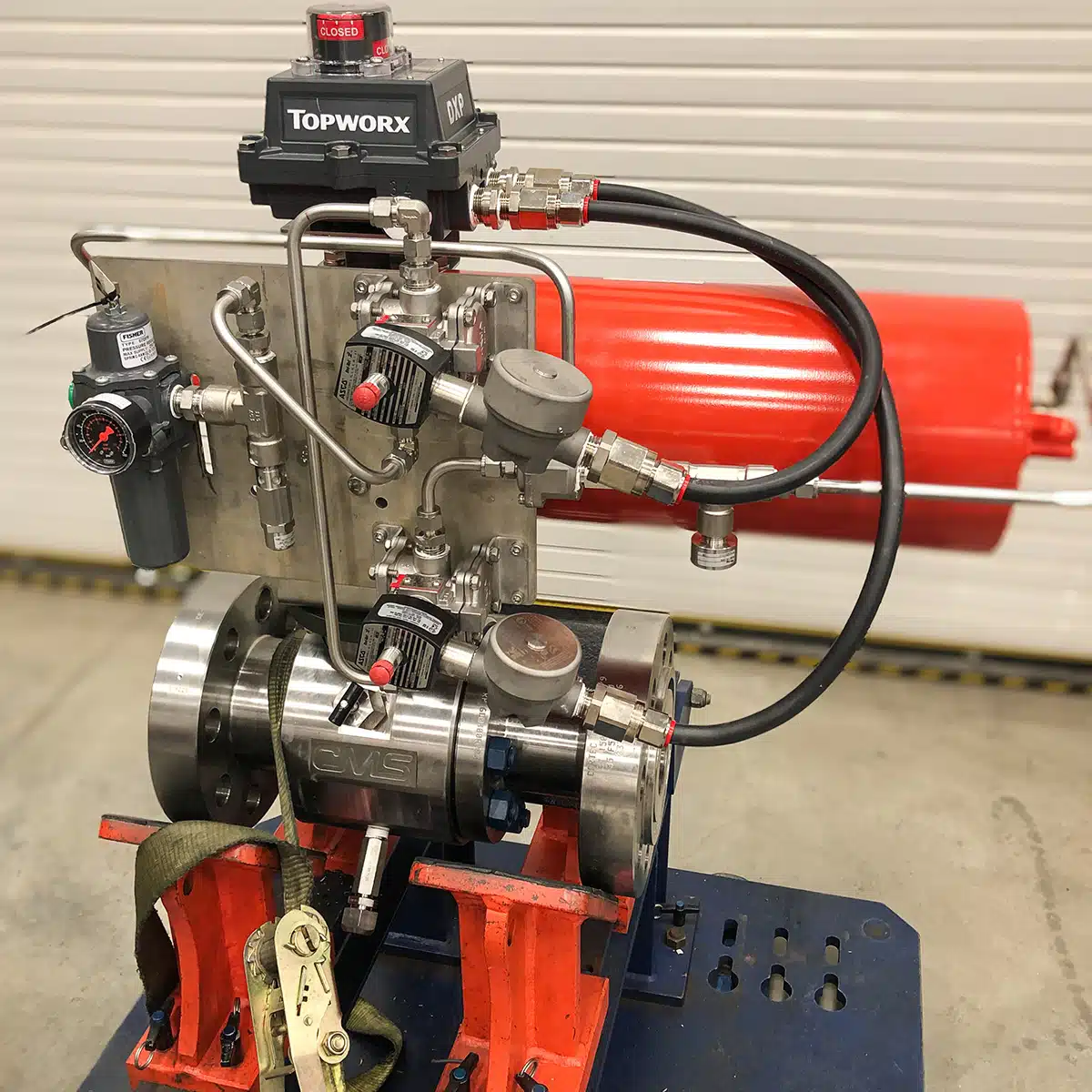

CORTEC is setting industry standards with reliable valves. In addition to industry-leading critical service API 6A valve products within the upstream oil and gas market, CORTEC offers an expanded valve range well suited to a wide range of energy industry applications. We manufacture our valve products under API 6A and 6D licenses. CORTEC provides a complete line of conventional flanged end API 6D ball valves, which benefit from our high-pressure and critical service application background. These models, configured with various sizing, material, and actuation options, include CORTEC’s advanced metal seated technology, which sets standards for high-integrity performance, and GRIT SHIELD™ technology, which prevents Seat Spring pack-off by flow media. Our adaptable manufacturing processes, in combination with our hands-on design and engineering experience, assure the end user a solution tailored to their preferences without compromising quality, value, and delivery.