Quality and Innovation

CORTEC uses only the highest quality materials to manufacture some of the most innovative yet easy to use choke designs known today. Each design is adaptable to meet changing well flow conditions over the life in the field.

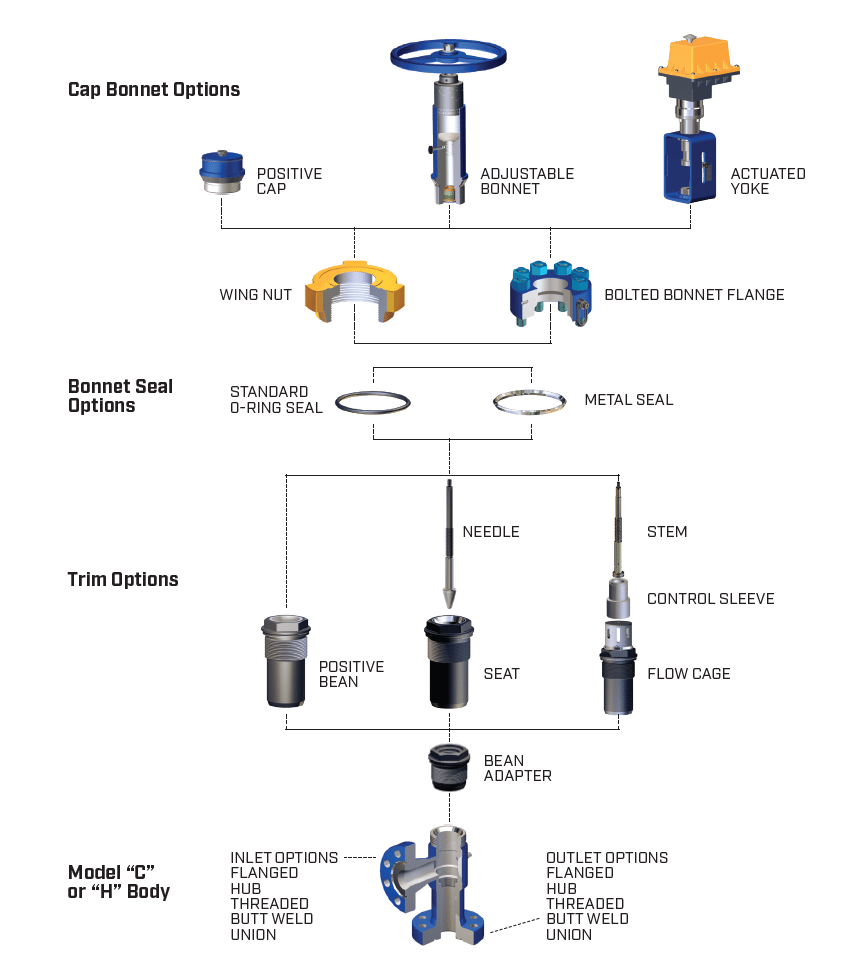

Choke Configurations

- Positive Bean Configuration

- Needle and Seat Configuration

- Cage and Sleeve Trim Configuration

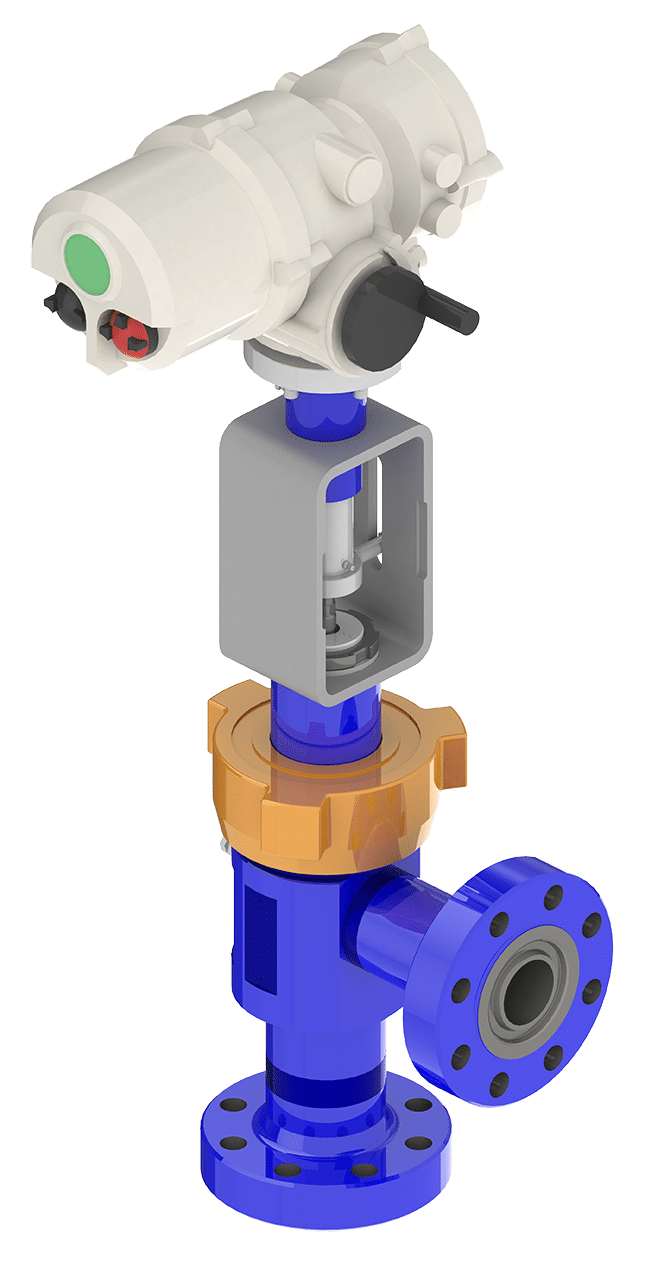

- Actuated (Electric, Pneumatic, and Hydraulic)

Specifications

- Orifice sizes ranging from 1/4” to 5”

- API 2,000—20,000 PSI CWP

- ANSI Class 600—2,500

- Severe Service Applications

- PSL 1, 2, 3, 3G, and 4

Quality Assurance

- API Specification Q1

- ISO 9001

- Built to meet or exceed API 6A Specifications

- Customer Specified Preferences

Models

Real-World Performance Advantages

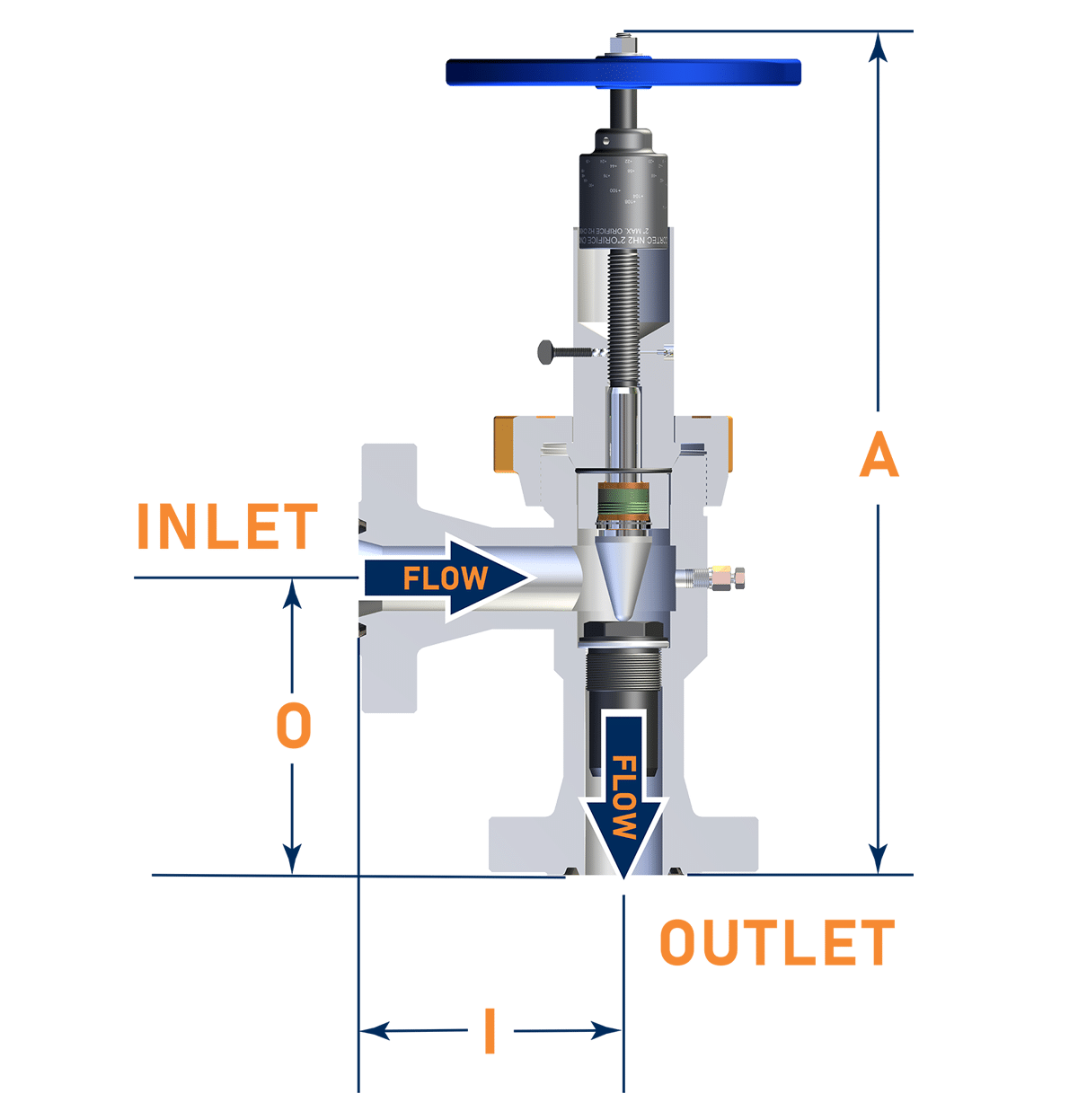

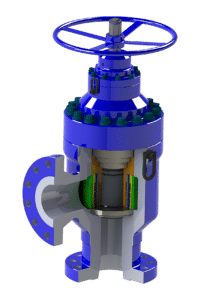

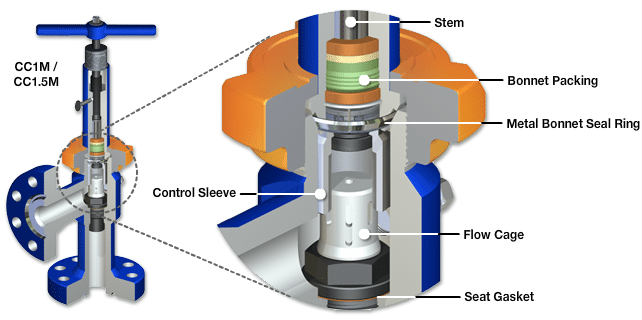

This high-performance model “CC” Control Choke design offers the oilfield operator specific performance advantages over the conventional needle trim options.

- Low Pressure Recovery Characteristics

- Erosion resistant prolonging trim life

- Pressure balanced to reduce torque

- For severe service applications including abrasive service

- ANSI Seat Class IV & V

- Firesafe

Features and Benefits

- Pressure balanced trim offsets high actuation force and allows for high differential pressures.

- Slotted sleeve provides smooth flow-to-lift transition that reduces noise.

- Maintains low-pressure recovery characteristics to offset potential cavitation and flashing.

- Seat and control sleeve sealing surfaces are not directly exposed to the high velocity flow.

- Highly effective shut-off that meets the practical demands of oilfield applications.

- Adapts to a wide range of inlet and outlet connections and dimensions.

- Fitted with a heavy duty severe service metal bonnet seal ring. (excludes Model “CC1”)

- This design offers “real-world” advantages to noise reduction, reduced cavitation in liquid service, reduced icing in gas service, extended service in abrasive environments, and positive shut-off.

| Model | Max Orifice | Max PSICWP |

|---|---|---|

| CC1/CC1M | 1" | 20,000 |

| CC1.5M | 1.5" | 15,000 |

| CC2M | 2" | 15,000 |

| CC3M | 3" | 15,000 |

| CC4M | 4" | 10,000 |

| CC5M | 5" | 15,000 |

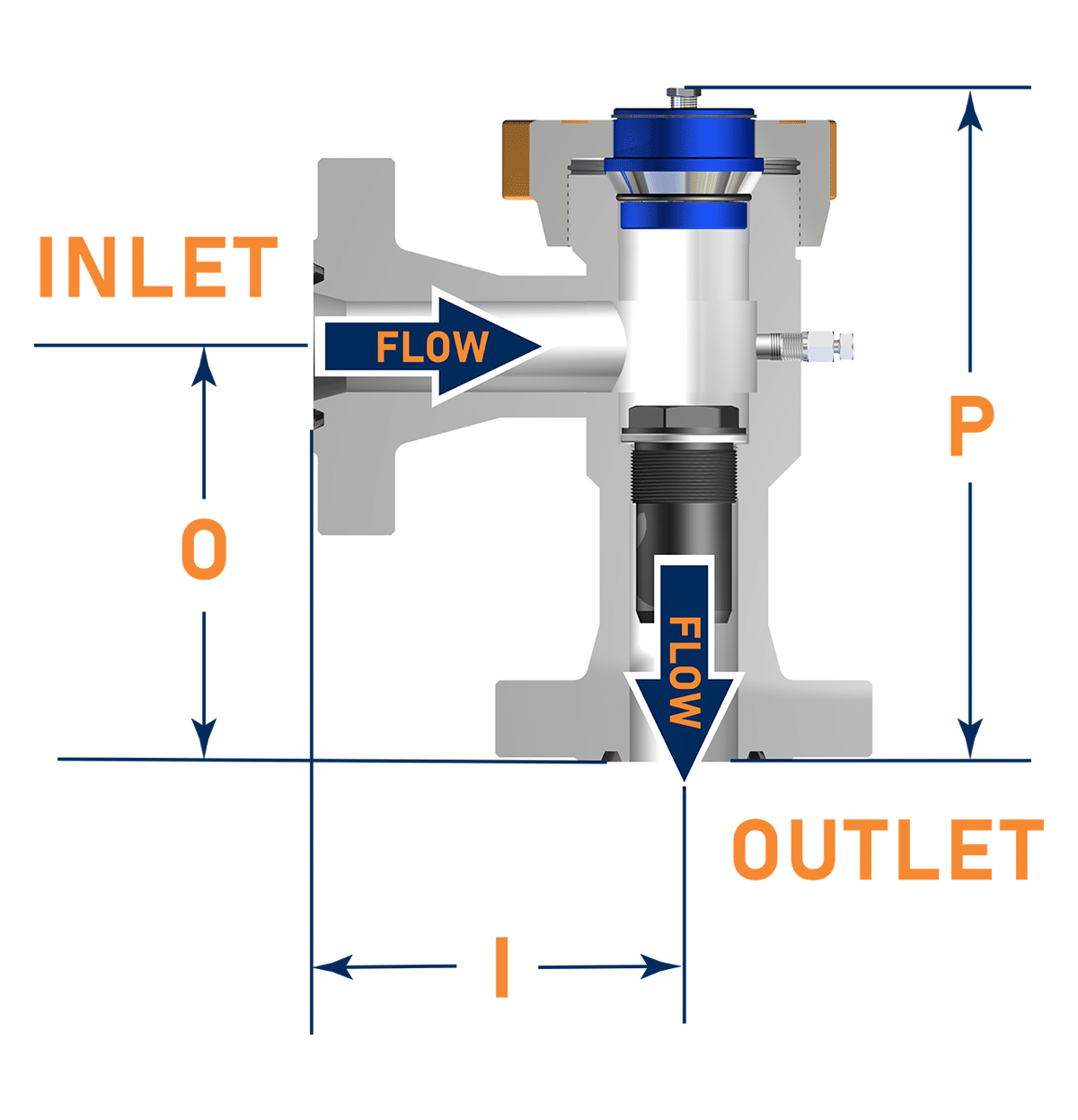

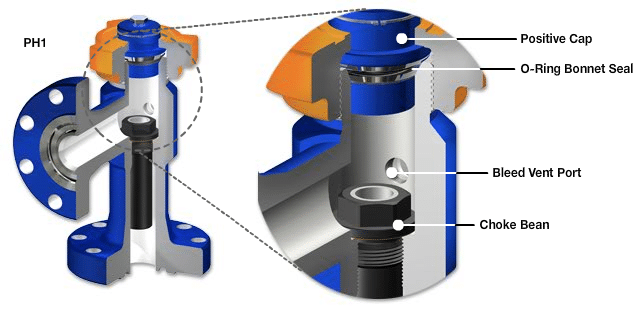

Economical and Easy to Maintain

The CORTEC model “PH” positive production choke offers the user a more economical design that is easy to maintain. The positive chokes are easily convertible to an adjustable choke.

The CORTEC positive choke offers a field proven design that is both economical and user friendly.

The simplest, most inexpensive configuration

- Engineered for heavy duty, maintenance free performance

- Parts are interchangeable with popular models

- Installation, parts replacement, and other field work are simple

Features and Benefits

- Field interchangeability with many other common H2 design components.

- Field convertible from positive to adjustable by changing out the bonnet assembly or cap assembly.

- Metal bonnet/cap seal is optional.

| Model | Max Orifice | Max PSICWP |

|---|---|---|

| PH1* | 1" | 10,000 |

| PH2* | 2" | 15,000 |

| PH1M* | 1" | 10,000 |

| PH2M* | 2" | 15,000 |

| PCH1M* | 1" | 15,000 |

| PC1M**** | 1" | 20,000 |

| PC3M | 3" | 10,000 |

| PC4M | 4" | 10,000 |

| PG8746** | 1" | 10,000 |

| PPC*** | 1" | 15,000 |

*These chokes are interchangeable with Cameron® model “H2”

**These chokes are interchangeable with the Gray® Model “8746”

***These chokes are interchangeable with FMC® Models “JWA” and “PC”

****This model is only available in 20,000 PSI

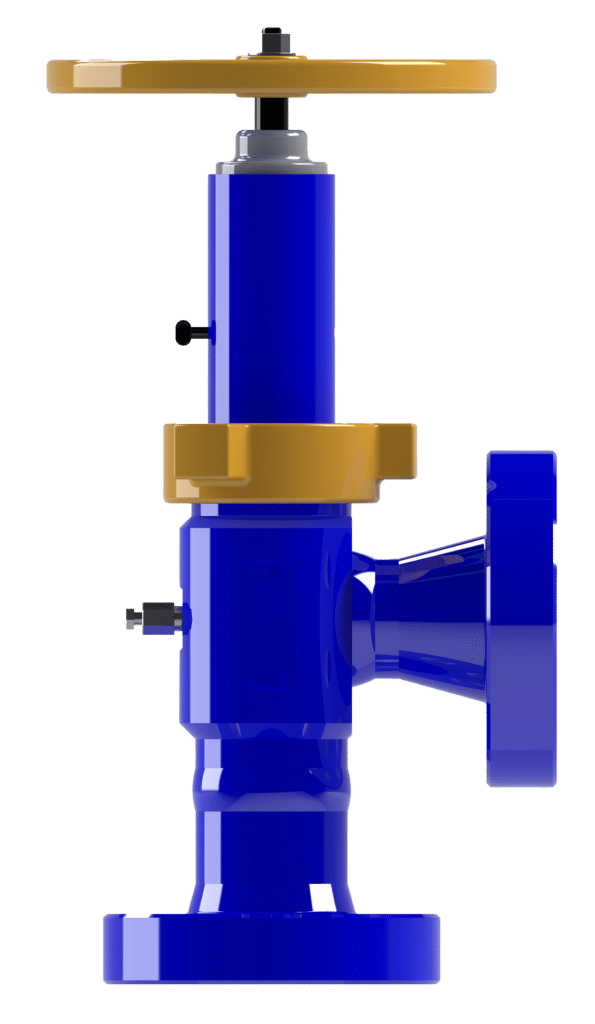

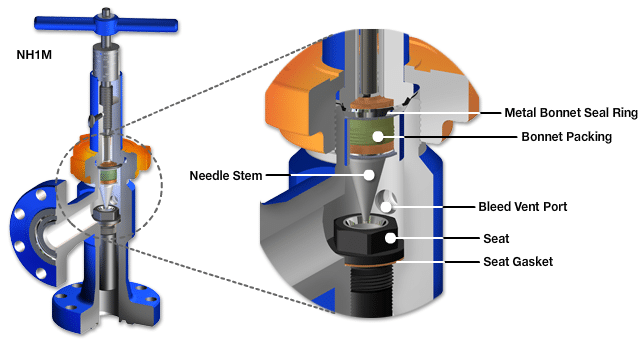

Trusted Worldwide for Decades

CORTEC Model “NH” adjustable chokes provide oilfield customers a well-established design that has been in service worldwide for decades. It is based on the typical Cameron® H2 design and offers field interchangeability with common components.

The CORTEC needle and seat trim choke offers an economy of operation and versatile utility in a traditional design that is familiar to oilfield personnel.

- Fully adjustable as flow rates and pressures fluctuate

- Easy to replace in the field

- Parts are interchangeable with popular models

- Suitable for low to medium pressure drops, less severe service

Features and Benefits

- Traditional angle body O-Ring bonnet.

- Interchangeable parts with many other Cameron® H2 style chokes

- Field convertible from adjustable to positive.

- Robust metal bonnet seal is optional.

- Optional “Spring Loaded Pressure Energized TFE” stem packing reduces operation torque, offers superior sealing characteristics, and is compatible with a wide range of chemicals associated with drilling and production.

| Model | Max Orifice | Max PSICWP |

|---|---|---|

| NH1* | 1" | 10,000 |

| NH2* | 2" | 15,000 |

| NH1M* | 1" | 10,000 |

| NH2M* | 2" | 15,000 |

| NCH1M* | 1" | 15,000 |

| N3CM | 3" | 15,000 |

| NC4M | 4" | 10,000 |

| NG8746** | 1" | 10,000 |

| NJWA*** | 1" | 15,000 |

*These chokes are interchangeable with Cameron® model “H2”

**These chokes are interchangeable with the Gray® Model “8746”

***These chokes are interchangeable with FMC® Models “JWA” and “PC”

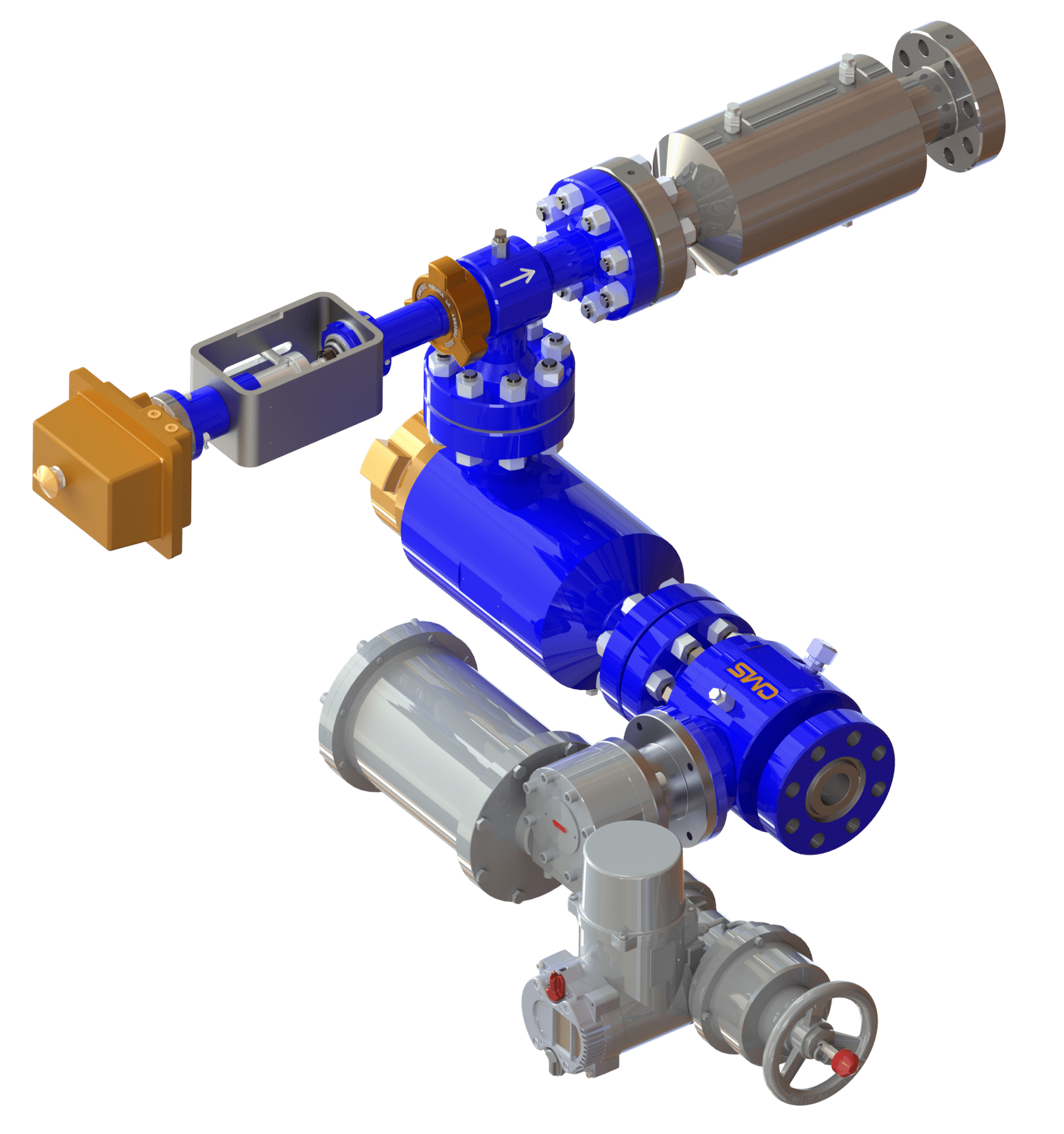

Let CORTEC be the single source for your complete wellhead wing solution

Across adaptable, robust choke designs and reliable, high-quality valve products, CORTEC can provide not only your choke and valve needs but all specialty flowline and automation requirements. Our facilities are licensed under API 6A (Houma 0700/Port Allen 1866), and our manufacturing capabilities include Tees, Crosses, Adapters, Spacers, and Flanges. CORTEC can supply virtually any common industry flowline component, including blast joints and instrument flanges commonly used in wellhead service.

CORTEC produces a full line of compact wellhead plug catchers, which can be installed upstream of the production choke to filter debris, resulting in greater choke performance and reduced production downtime. Our automation team is versed in all common industry requirements, and CORTEC commits to a substantial stocking of actuator options, including Emerson, Rotork, and other OEM options.

Chokes

- Configurations: positive bean, needle and seat, cage and sleeve and rotary trim.

- Orifice sizes: ¼” to 5”

- Pressure class: API 2,000 to 20,000 PSI CWP.

- NACE Compliance

- API 6A Specifications (PSL 1, 2, 3, 3G and 4)

Valves

Trunnion models

- Bore sizes: 1.5” to 24”

- Pressure classes: API 2,000 to 20,000 PSI CWP.

- Available in both compact and conventional flanges in options with materials and coating options to meet virtually all energy industry needs.

- HVOF tungsten carbide metal seated applications.

- API licensed to provide surface safety valves and boarding shutdown valves.

- Industry standards: API 6A, API 6AV1, API 6D, ASME 16.34

- API 6FA/607 Fire Rated Designs

- SIL 3 (available upon request)

Read more about CORTEC Valves here

Automation

In addition to actuating our choke and valve products, CORTEC’s automation department possesses a wealth of experience automating energy industry operations.

- Drilling, Well Service, and Production Operations.

- Choke and Valve Control Panels

- Drilling Choke setpoint Systems

- Pressure Relief Systems

Read more about CORTEC Automation here

Flowline Components

CORTEC can supply a variety of flowline and piping accessories for almost any connection type in a full range of sizes, pressure classes, and materials to suit and service any application.

Read more about CORTEC Flowline Components here

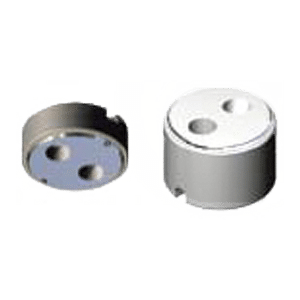

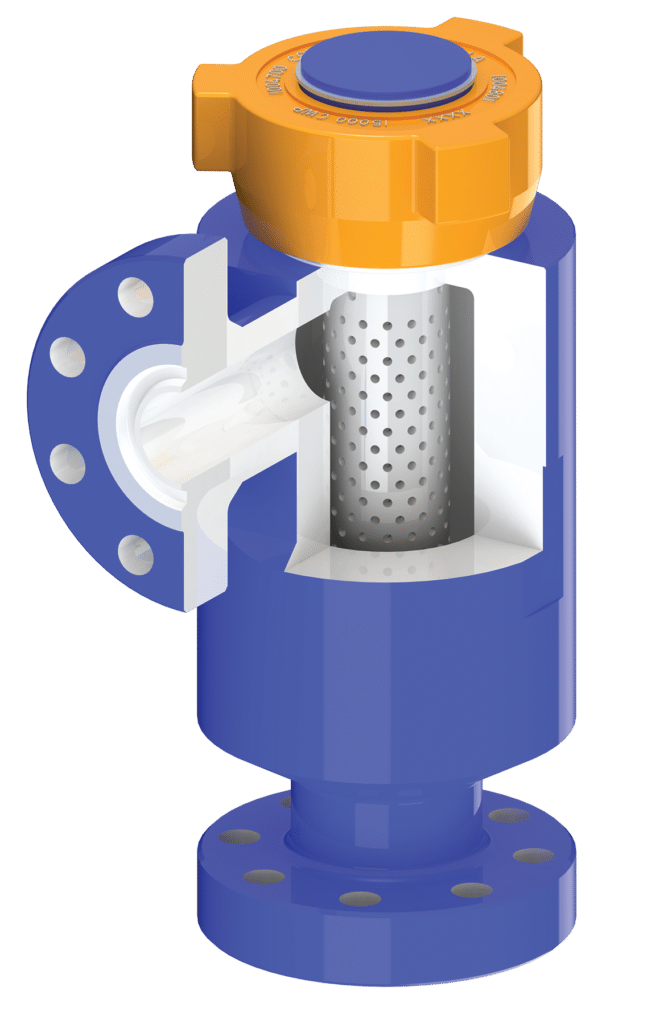

Plug Catchers

CORTEC has a full line of Wellhead Plug Catchers that can be installed upstream of a production choke. This device will serve to minimize downtime and prolong choke trim and body life in applications where extreme solids and abrasives are present.

Read more about CORTEC Wellhead Plug Catchers below.

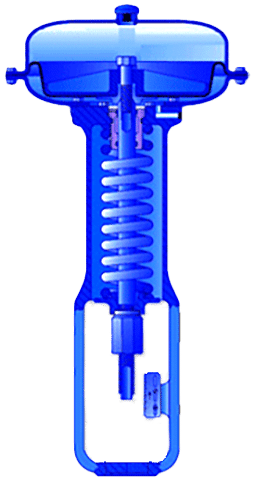

CORTEC can supply a full line of Wellhead Plug Catchers to be installed upstream of a production choke. This device will serve to minimize downtime and prolong choke trim and body life in applications where extreme solids and abrasives are present. CORTEC clients are now utilizing these field-proven devices on hundreds of shale wells offering considerable operational value.

Offered in a range of flange and pressure classes from 5 to 15K, these devices can be configured to suit the needs of any common wellhead application. CORTEC can offer in the field training to ensure proper service and maintenance

requirements are met.

The device has been evaluated and sized by the CORTEC engineering team to accommodate significant plugging and still provide full capacity flow. The screen design has been field-proven and designed through consultation with field operators.

PLUG CATCHER MODELS

2-1/16” - 5k

2-9/16” - 5k

3-1/8” - 5k

1-13/16” - 10k

2-1/16” - 10k

2-9/16” - 10k

3-1/16” - 10k

1-13/16” - 15k

2-1/16” - 15k

2-9/16” - 15k

3-1/16” - 15k

CORTEC Wellhead Plug Catchers provide value in the field by filtering out large debris before it clogs or damages flow control equipment and improving choke service life and minimizing down time.

CORTEC Wellhead Plug Catchers filter damaging solid and abrasive materials such as fracing or plug debris.

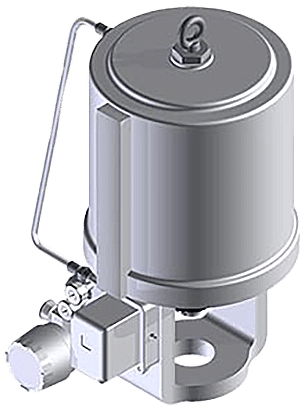

Actuation

CORTEC can supply virtually any other OEM actuator or associated instrumentation to complement its comprehensive range of chokes and valves. Advanced actuators and instruments are available for a complete flow control solution. Packages can be tailored specifically to a customer’s project needs. Below is a list of common actuation types and offerings.