CORTEC Products are Built for the Pressure

Our slogan, 'Crafted For Confidence,' is more than just a simple tagline. It's our mission. We are committed to providing reliable products and services that instill confidence in our end users. When you see CORTEC on the product, you can be assured it is reliable, safe, and fit for purpose.

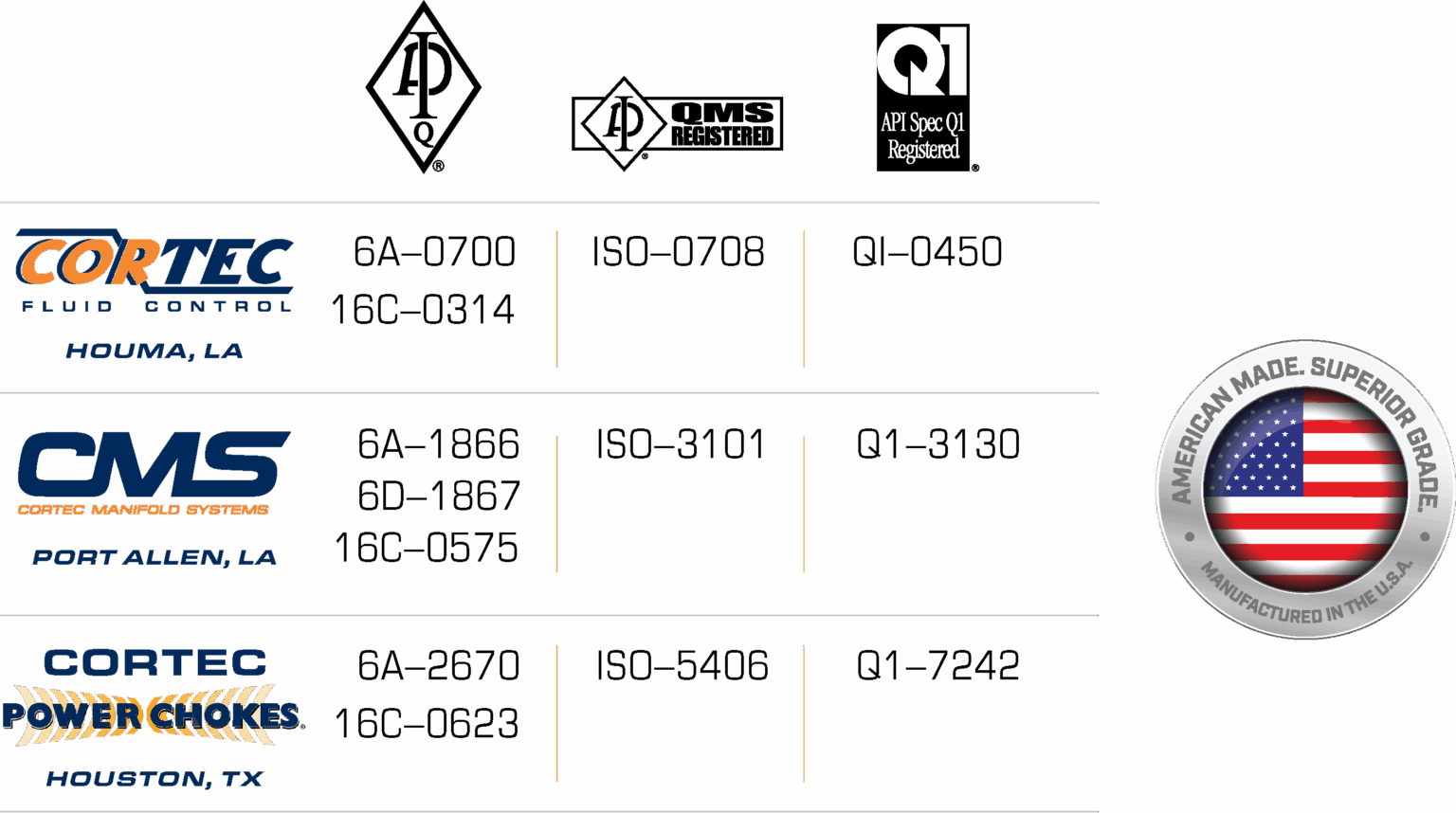

We hold the necessary quality accreditations to meet or exceed the American Petroleum Institute Specification 6A, 6D, and 16C licenses. Our quality management system is registered in accordance with API Q1 and ISO 9001 International Quality Management Standard, ensuring that our products and services meet the highest industry standards.

At CORTEC, we place a high value on maintaining strong relationships with our customers. Our commitment to service and quality ensures that every project we undertake aims for complete customer satisfaction. Our service personnel are equipped with all the necessary credentials and certifications for work in both onshore and offshore facilities.

As a manufacturer, CORTEC is here to support our customers' needs with a full inventory of replacement parts. Our team is focused on providing superior service to your organization backed by industry leading product and manufacturing quality.

CORTEC Meets or Exceeds Industry Standards

CORTEC is licensed to API 6A, 6D and 16C. Our quality system is registered to API Q1 and ISO 9001. As a testament to our commitment to ongoing quality improvement, CORTEC is an active participant on several API standard committees, where we work alongside our peers to push to advance reliability and safety in the industry

To obtain a copy of CORTEC’S quality policy or any of our quality accreditation certificates, please contact us at sales@uscortec.com

CORTEC and all other OEM API licenses can be confirmed at API’s composite search list – Composite List (api.org)

CORTEC believes that nothing is more important than safe, reliable product performance.

Our experienced team is fully equipped with the tools to perform comprehensive testing on model prototypes, which ensures the design processes and analytical verifications result in a proven, validated product.

Our rigorous testing process ensures that all our products are subjected to extreme conditions, pushing them well beyond their expected operating limits. This process guarantees that our valve models thrive in the most punishing in-service environments, providing our clients with the assurance of high-quality and reliable products when it matters most.

With our comprehensive in-house testing capabilities, we can ensure that our products are durable to the extreme, meeting and exceeding industry standards and requirements every step of the way. CORTEC’s in-house testing capabilities include hydrostatic and gas testing up to 30,000 PSI. Additionally, we possess testing assets such as an API 6A Annex F environmental test chamber, a hyperbaric subsea test unit, and extensive torque testing to verify and enhance valve actuation requirements. CORTEC manufacturers a full line of API 6A Monogrammed Boarding Shutdown Valves (BSDV) meeting all of the requirements of BSEE (30 CFR, Part 250, Subpart H). All BSDVs are API 6A Annex F, API 6AV1 and API 6FA validated for the harshest environments. In addition, CORTEC offers BSDVs in custom bore sizes, fully in compliance with API 6A, to closely match our customer’s riser systems.

Safety and reliability are at the core of every product we manufacture and project we supply. CORTEC thoroughly validates each model before it is used in the field.