Setting industry standards with field-adaptable Well Control and Extreme Service Chokes designs

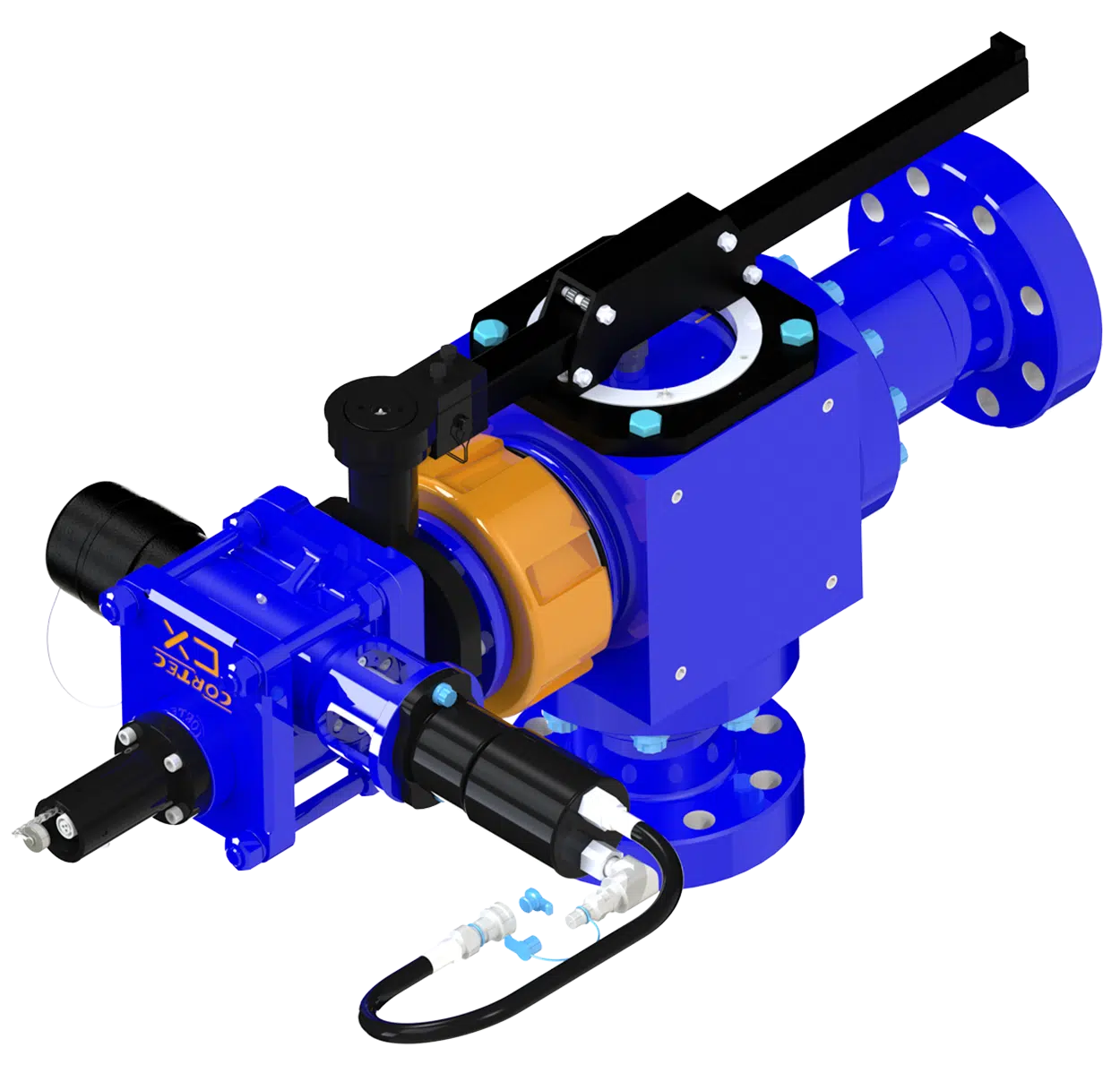

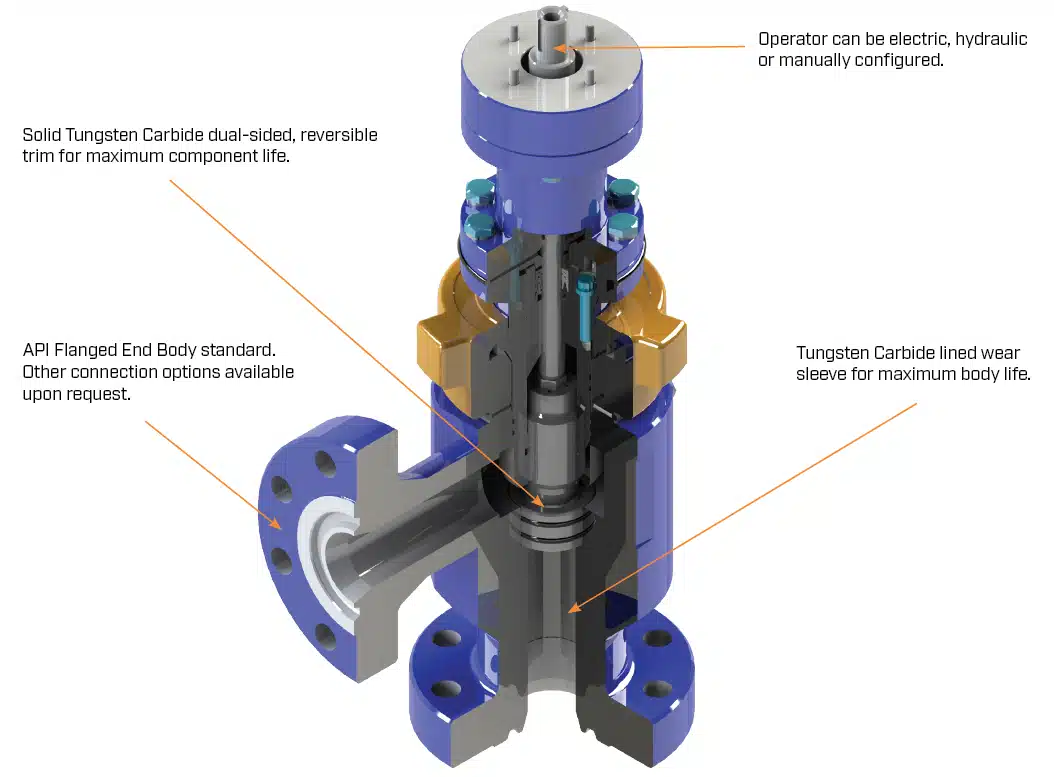

CORTEC Well Control/Extreme Service Chokes are engineered and manufactured to offer the oilfield operator increased service life and cost savings in high-pressure applications where substantial amounts of solids and abrasives are present. CORTEC manufactures a complete line of extreme service chokes that are designed to maximize performance within abrasive applications like well control, drilling, frac flowback, coil tubing, and snubbing. In addition to the rugged design of the choke internals, CORTEC recognizes the need for field-friendly maintenance and serviceability by offering optional gantry and tooling packages to round out a complete operating system.

Models

The CORTEC MODEL CX extreme service chokes are the most adaptable in the industry, manufactured to suit any drilling or well control service operation while meeting or exceeding industry requirements. Our team has the engineering expertise and experience to help you select the appropriate model for your operational needs. CORTEC’s industry-leading commitment to inventory stocking and customer service ensures you the highest efficiency in cost-of-ownership and the confidence in minimizing downtime.

CORTEC MODEL CX-2.0

2” Maximum Orifice

Up to 20,000 PSI

CORTEC MODEL CX-3.0

3” Maximum Orifice

Up to 15,000 PSI

CORTEC MODEL CX-4.0

4” Maximum Orifice

Up to 5,000 PSI

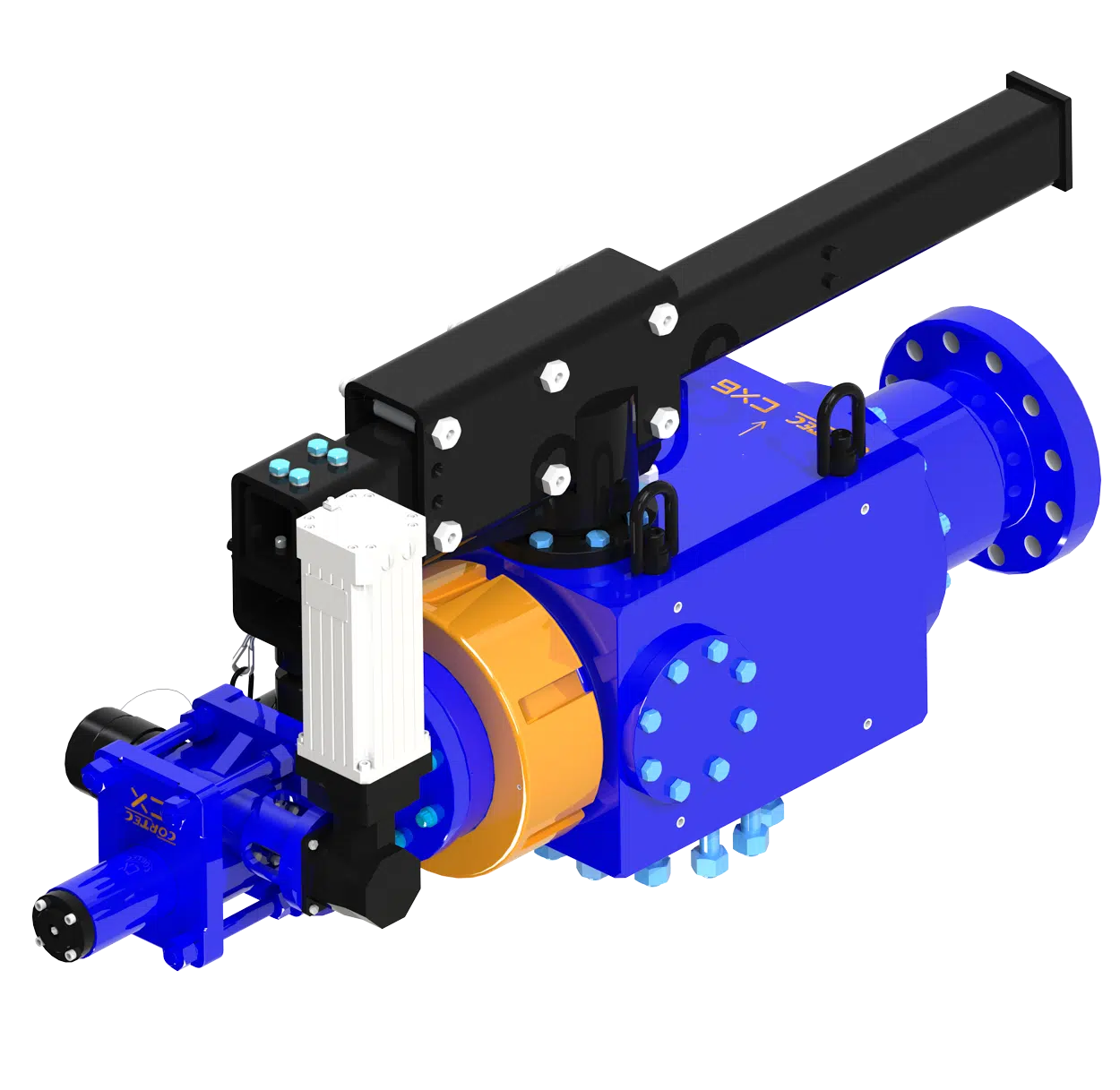

CORTEC MODEL CX-6.0

6” Maximum Orifice

Up to 5,000 PSI

The CX family can be configured in either hydraulic double-acting piston or worm gear (electric, hydraulic, or manual hand wheel) operators. The block body design allows for full versatility from studded, flanged, threaded, and hub connectors that can meet a full spectrum of industry and customer dictated dimensional requirements. Most models can be offered with optional trim orifice reduction kits, greatly expanding the optimal flow rate capacity range of an individual choke asset.

OVERVIEW

CORTEC Model CX-C2.0 offers the most economical option of the CX family of chokes. While retaining many of the robust design features of the CX product line, the CX-C2.0 design utilizes a fabricated “H2” profile flanged-end body, allowing seamless integration for any customer that deploys this body design into their existing or future operations. CORTEC Well Control/Extreme Service Chokes (CX) are engineered and manufactured to offer the oilfield operator increased service life and cost savings in high-pressure applications where substantial amounts of solids and abrasives are present. CORTEC manufactures a complete line of extreme service chokes designed to maximize performance within abrasive applications like well control, drilling, frac flowback, coil tubing, and snubbing.

OVERVIEW

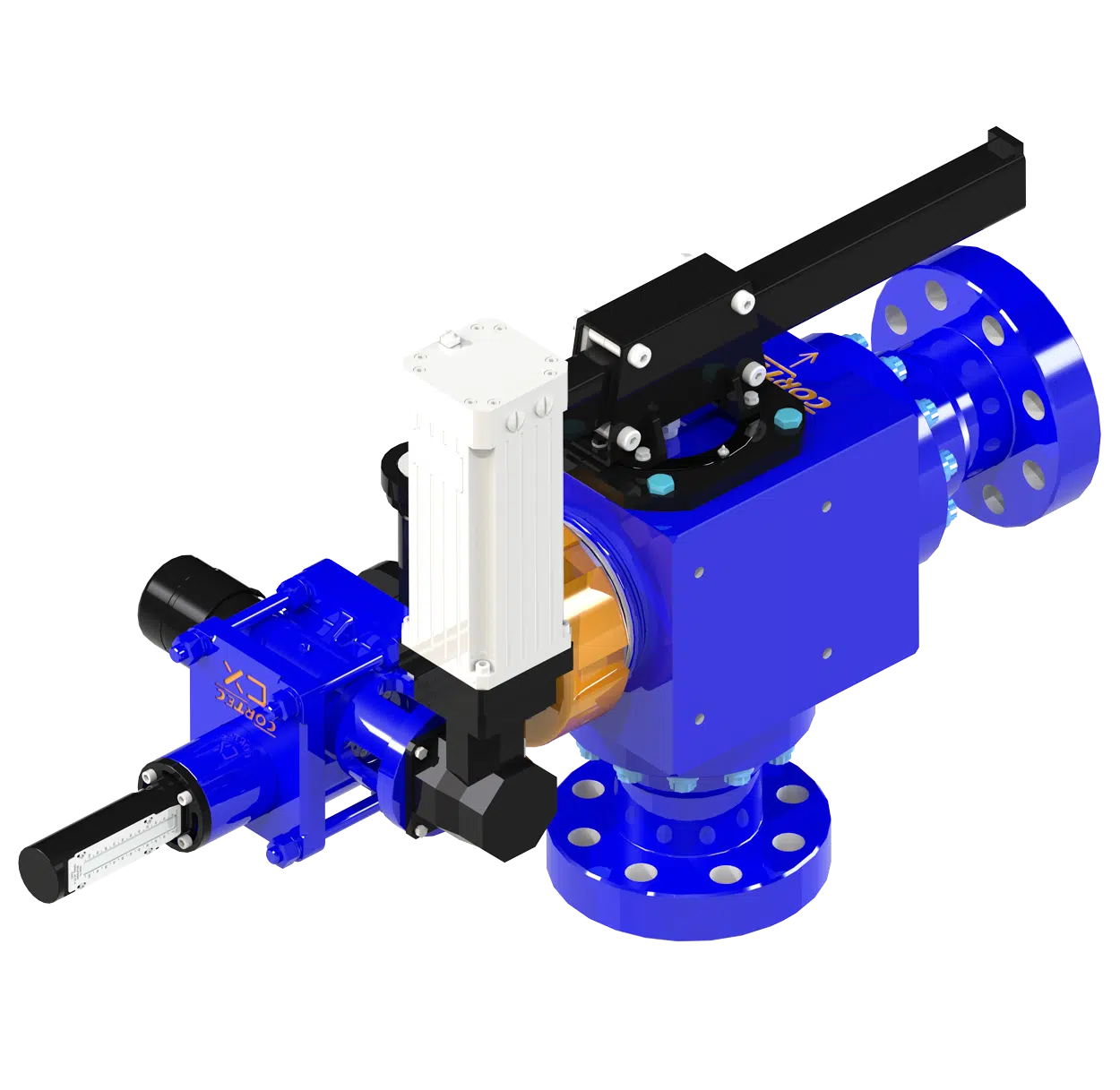

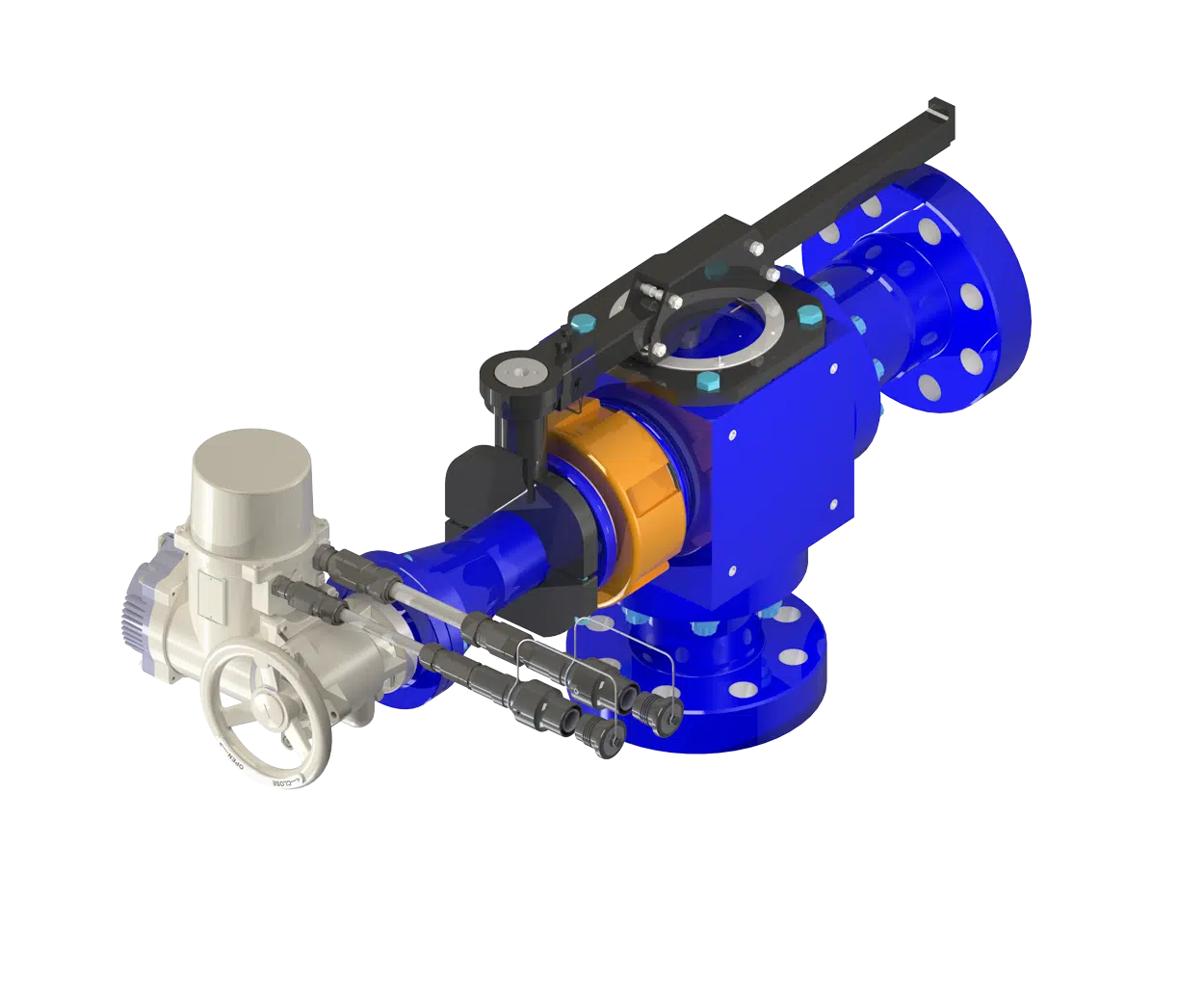

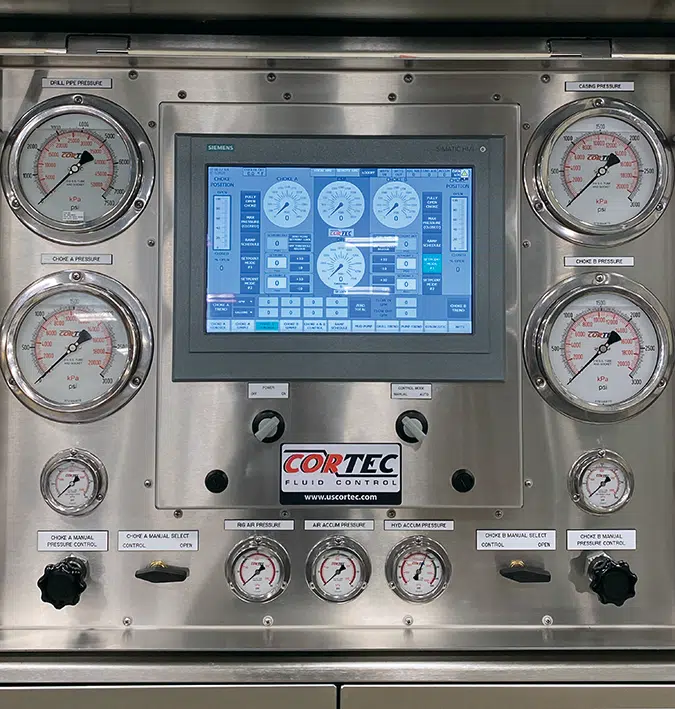

The CORTEC CX-HB3.0 Choke System is designed to offer drilling operations an increased level of value and functionality within MPD, UBD and other drilling setpoint applications. The CX-HB3.0 control panel is dual choke capable unit and can be controlled via a compact remote panel that can be installed in close proximity to the driller. This system exceeds the level of response and precision of many existing options within the market today at a value point operators can afford.

OVERVIEW

CORTEC is setting industry standards with field adaptable choke designs. CORTEC setpoint systems integrate field-proven choke designs with remote operation capabilities to add value and consistency to an end user’s operations. The CORTEC CX-EC 3.0 Setpoint System is electrically operated and has consistently been demonstrated to maintain desired pressure settings within MPD operations in pressures up to 3,000 PSI. The choke utilizes standard CORTEC CX body design and components with a ball screw operator, which can be driven by suitable actuation options. This system provides an efficient, cost-effective solution that maximizes setpoint performance with lower voltage requirements. This bonnet setup can be retrofitted and assembled onto many standard CORTEC CX models existing in the field. The setup offers the same field-friendly maintenance and robustness customers have come to appreciate within the CORTEC choke family.

OVERVIEW

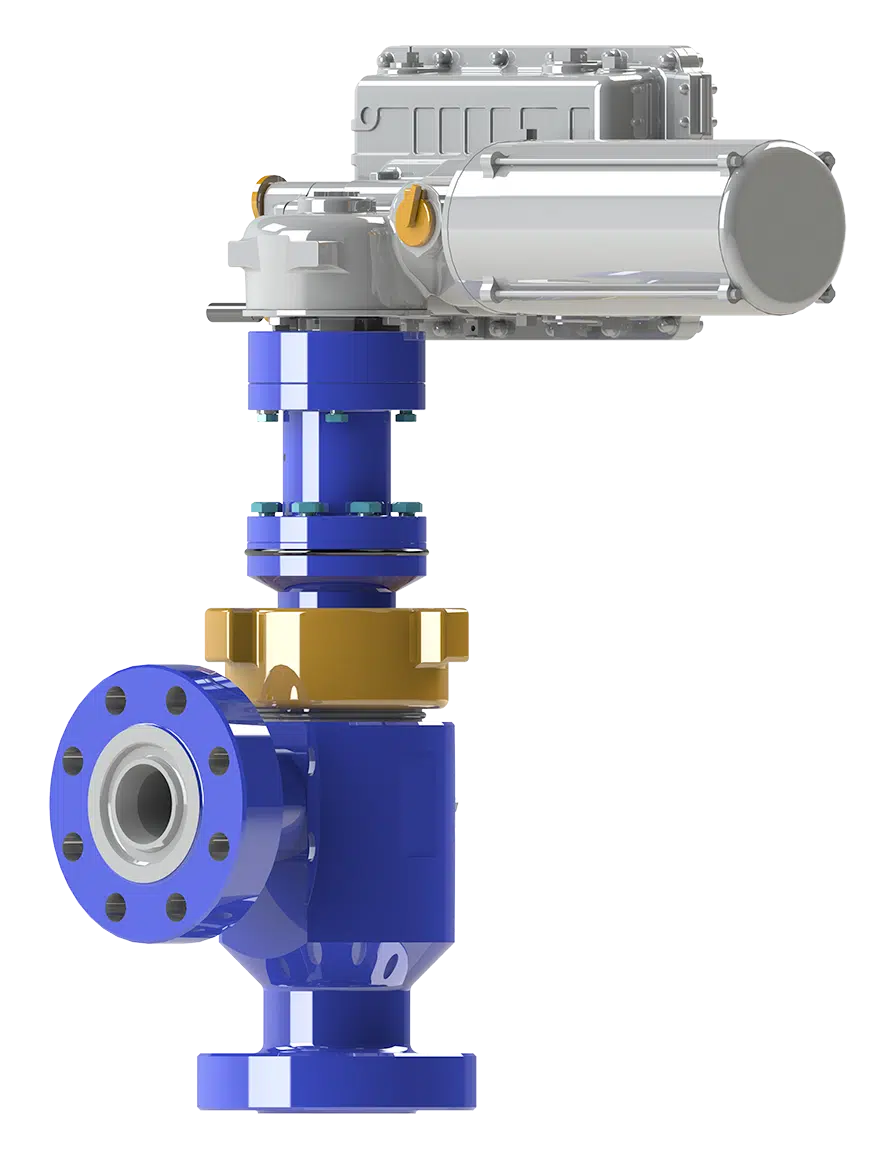

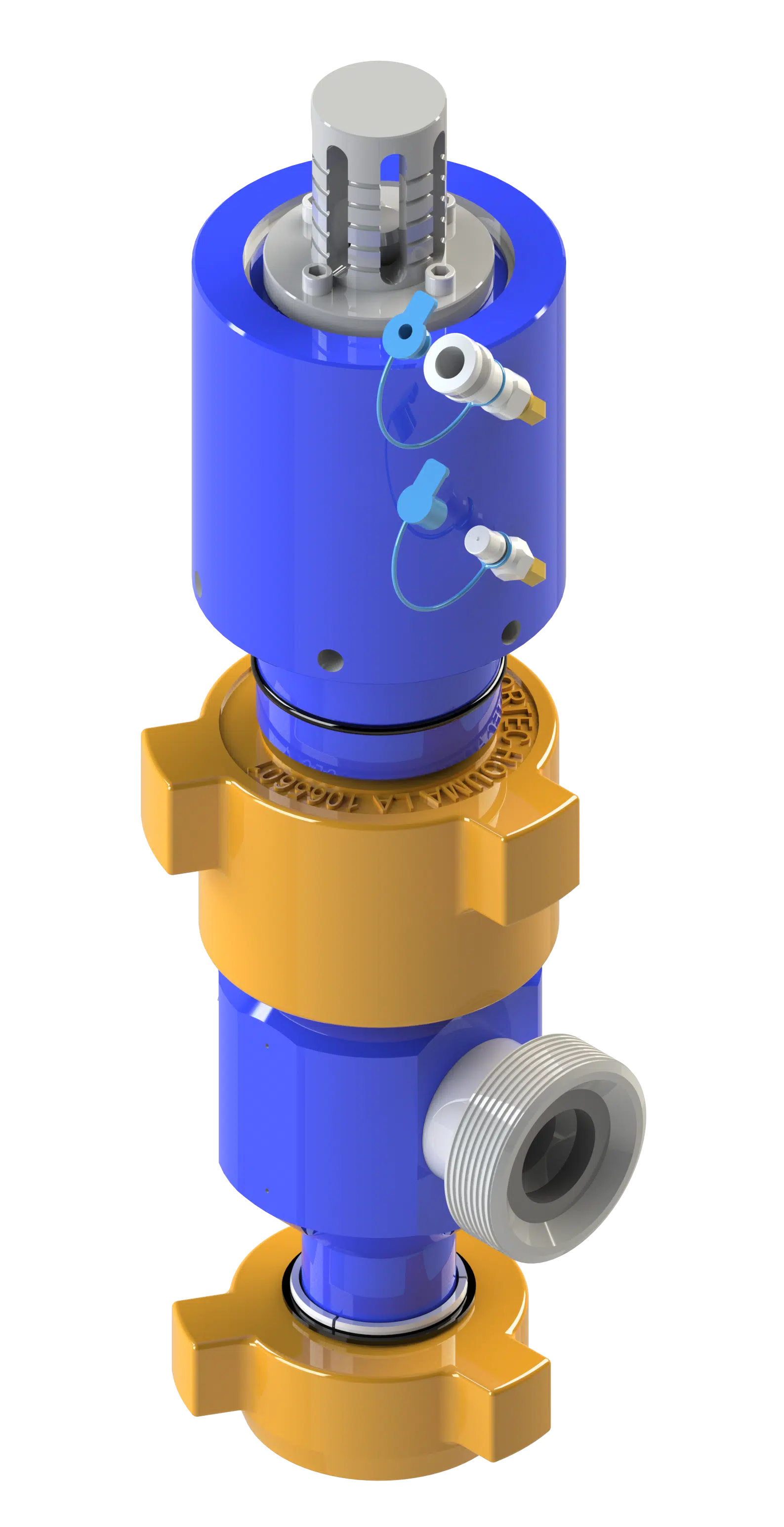

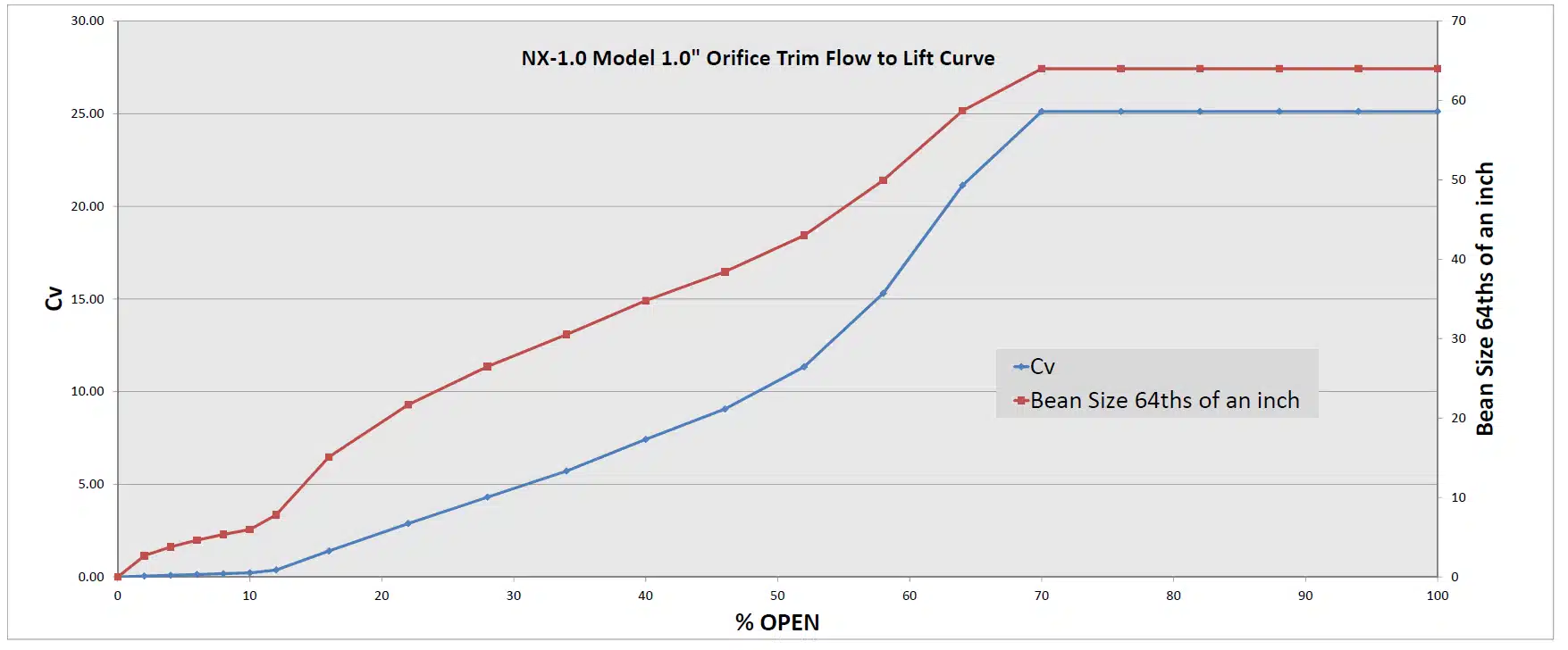

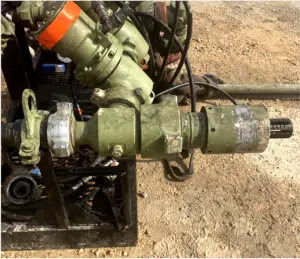

The CORTEC NX1 Choke is a field-proven hydraulic choke model designed to increase service life while providing a significant amount of cost savings and efficiencies during harsh drilling applications. We are thrilled to be able to offer our customers this unique compact choke and control solution that requires minimal maintenance in the field.

CORTEC uses only the highest quality materials to manufacture some of the most innovative yet easy to use choke designs known today. Each design is adaptable to meet changing well flow conditions over the life in the field.

CORTEC has successfully completed the field trial of the new remotely operated NX1 model hydraulic choke. The NX1 is an ideal option for applications requiring a compact 2” 1502 choke layout where remote operation is preferred. Designed to fit within the place of a standard 1502 Choke Tee, the NX1 is easily adapted into existing manifolds. The Choke is offered with a range of union or flanged end connections. This lightweight design offers a 1” maximum orifice and is rated up to 15,000 PSI CWP.

CORTEC has successfully completed the field trial of the new remotely operated NX1 model hydraulic choke. The NX1 is an ideal option for applications requiring a compact 2” 1502 choke layout where remote operation is preferred. Designed to fit within the place of a standard 1502 Choke Tee, the NX1 is easily adapted into existing manifolds. The Choke is offered with a range of union or flanged end connections. This lightweight design offers a 1” maximum orifice and is rated up to 15,000 PSI CWP.