CORTEC recently shipped three turnkey manifold systems out for a major deepwater project. The package included two API 9” 10,000 PSI boarding shutdown valve assemblies and an API 5-1/8” 10,000 PSI gas lift assembly.

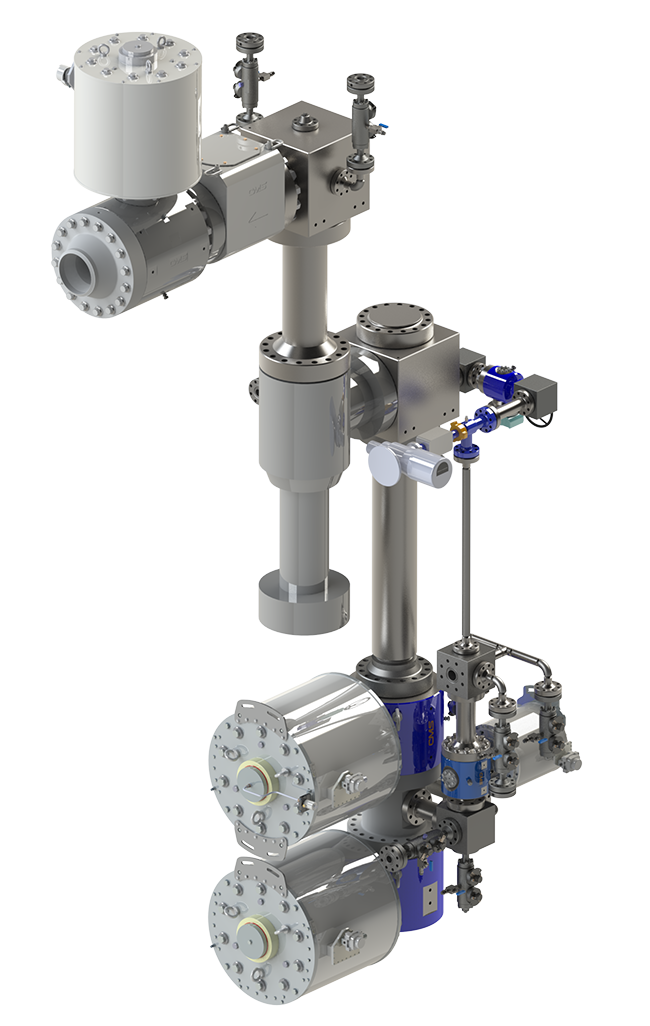

Two API 9” 10,000 PSI Boarding Shutdown Valve Assemblies

Each consists of two CORTEC model LDA090010MS 9” bore API 6AV1 PSL-3 metal seated ball valves with ATC hydraulic actuators; LDA030610MS 3-1/16” bore API 6AV1 PSL-3 metal seated ball valves with ATC hydraulic actuators; model TLDB005015MS 1/2” bore SS metal seated double block and bleed ball valves; model CC1ES 1-1/13” 10K electric actuated choke valves; API 9” 10K machined barred tees; and miscellaneous API 6A studded blocks and flanged spools.

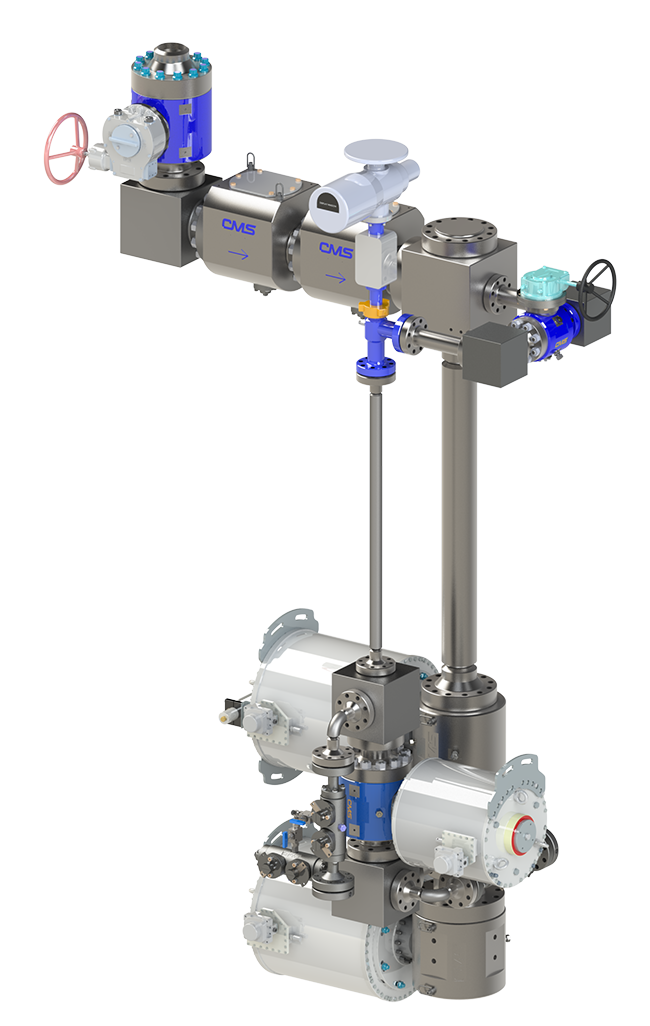

One API 5-1/8” 10,000 PSI Gas Lift Assembly

Consists of two CORTEC model LDA051210MS 95-1/8” bore API 6AV1 PSL-3 metal seated ball valves with ATC hydraulic actuators; LDA030610MS 3-1/16” bore API 6AV1 PSL-3 metal seated ball valves with ATC hydraulic actuators; model TLDB005015MS 1/2” bore SS metal seated double block and bleed ball valves; model CC1ES 1-1/13” 10K electric actuated choke valves; API 5-1/8” 10K machined barred tees; and miscellaneous API 6A studded blocks and flanged spools.

All of these assemblies were API 6A PSL3G gas tested as well.