Designed to be Compact and Field-friendly

CORTEC diverter valves are designed to offer the end user a robust, reliable design that is compact and field-friendly. From tight area rig substructures to manifold 3-way diversion requirements, CORTEC can supply a design to meet your project needs.

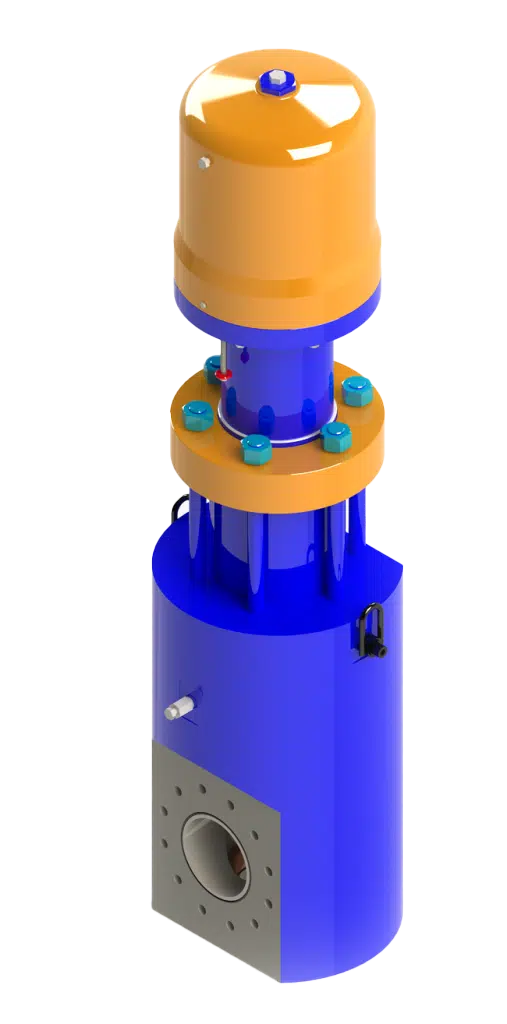

Poppet Diverter Valves

Designed for Fast and Easy Diversion of Flow

The CORTEC “PD” Poppet Diverter Valve offers a three-way diversion of flow when space and weight are critical.

This valve is designed for fast and easy diversion of flow between production and test headers.

Features and Benefits

- Simple, low-cost conversion to automation.

- Actuator operates pneumatically, hydraulically, or with field gas.

- Linear operation increases seat durability.

- Upper seat is isolated from the flow path.

- Inlet can be located on either side.

- Multiple lifting points on valve body for easy field installation.

- Positive spring return allows for fail to lower port when a loss of pressure occurs.

- Reliable design, easy replacement and service.

- Wide open flow zones reduce seat wear, maintenance, and vibration.

- Size ranging from 2″ through 6″

- ANSI CL1500 to 6,170 PSI working pressure

- Bore is sized to common piping schedules

- Available in almost any size and type end connection

- Designed to API 6FA design criteria

- Hydraulic or Pneumatic Actuator assemblies

- Low-pressure actuation

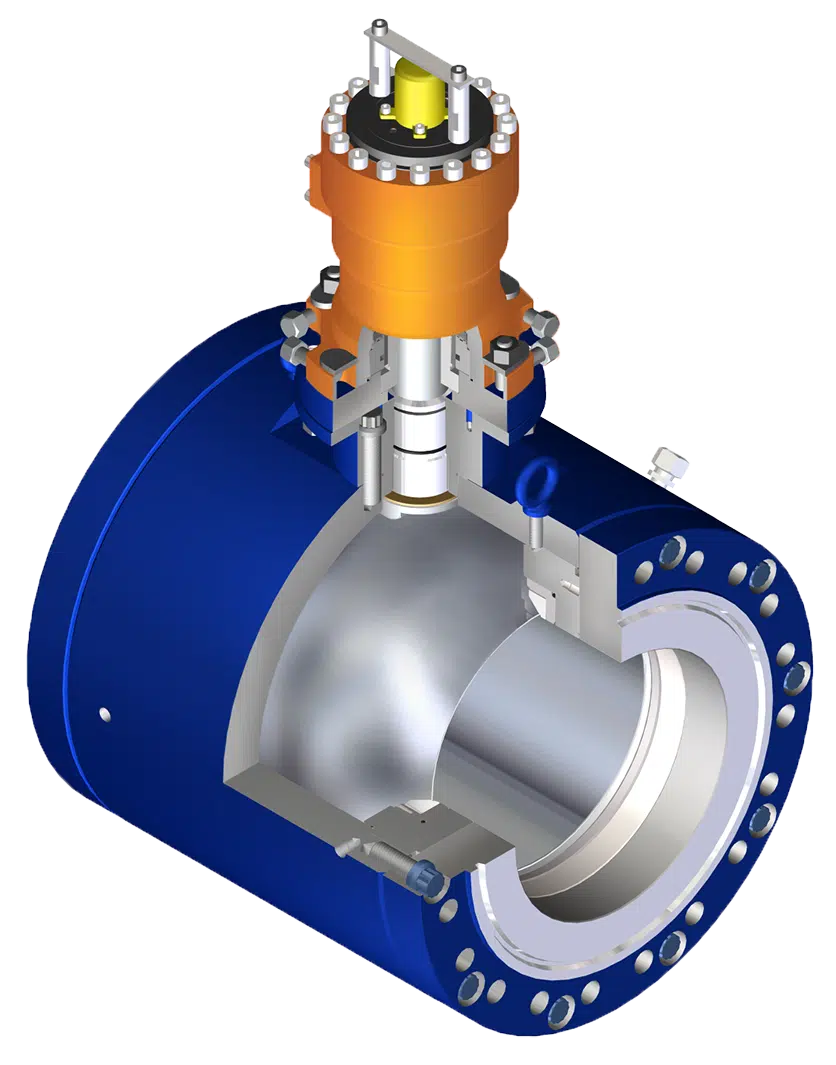

Drilling Diverter Valves

A Compact Design for Onshore and Offshore Drilling

The CORTEC DDV Drilling Diverter Ball Valve can be used for onshore and offshore drilling where there is a need for a more compact valve design.

This valve is designed for high performance drilling applications and abrasive service.

Features and Benefits

- Multiple lifting points for easy field installation.

- External travel adjustment screws make adjustments easy.

- Cap screws allow for easy flange removal.

- Grease fitting facilitates routine lubrication.

- Standard visual position indication or pneumatic, electric and hydraulic options.

- Size ranging from 10″ through 12″

- Available in 300, 600, & 900 class working pressure

- Available in multiple bore sizes

- Available in almost any size and type end connection

- Designed to API 6FA design criteria

Uses:

- Fill-up and trip type applications.

- Motion compensation and Riser Tensioning System control valve applications.

- Riser Booster line valve applications.