Leading the Industry: CORTEC's Innovative High-Performance Compact Valve Solutions

In 2006, CORTEC resolved to develop an innovative, high-performance compact valve that maximized weight and space savings while delivering superior value to our end users. Today, we manufacture a complete line of ball valves spanning API 6A and 6D designs with models ranging up to 24” bore and 20,000 PSI. Our Port Allen facility produces these products from raw materials to finished, validated results.

This state-of-the-art facility is supported by a highly experienced engineering team and is equipped with advanced technology that covers all design, testing, and manufacturing needs, resulting in industry-leading products. Our mission is to surpass industry and customer requirements by providing products and customer support that can be trusted for decades.

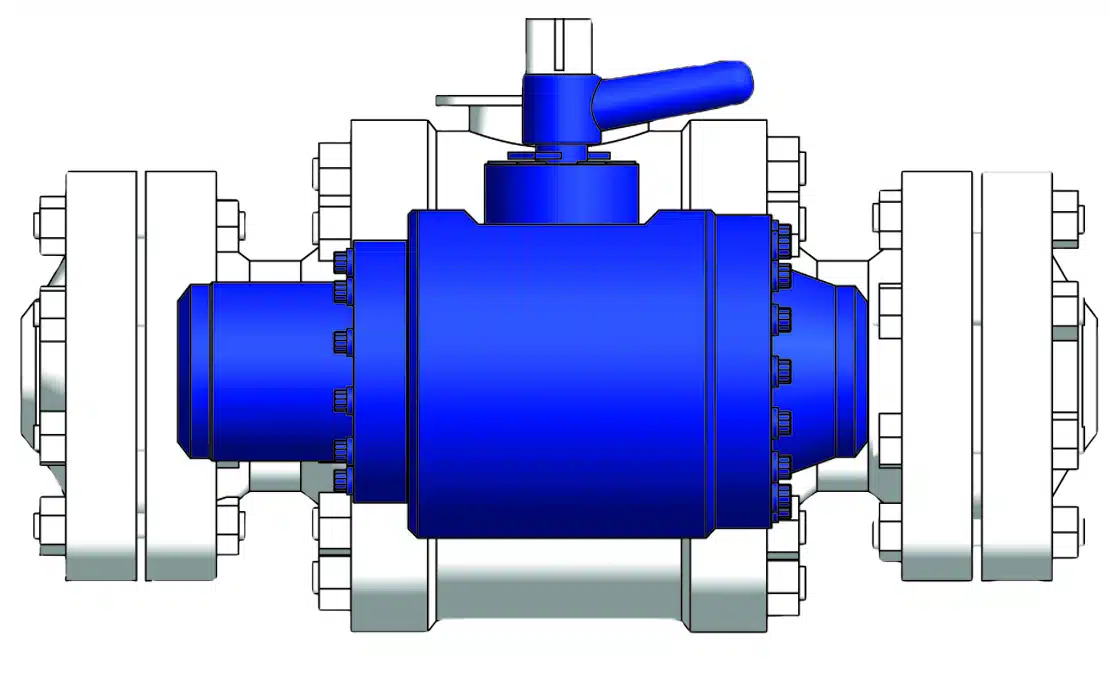

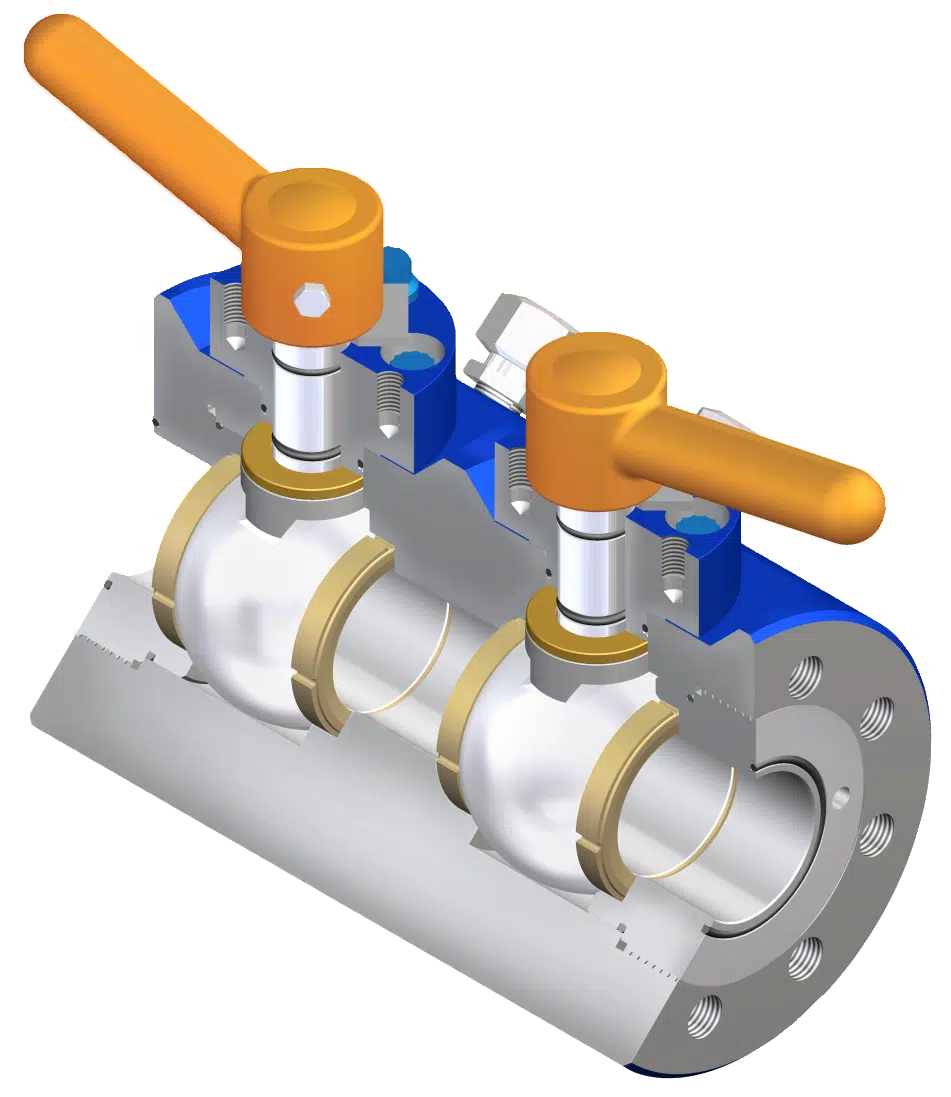

Compact Ball Valves

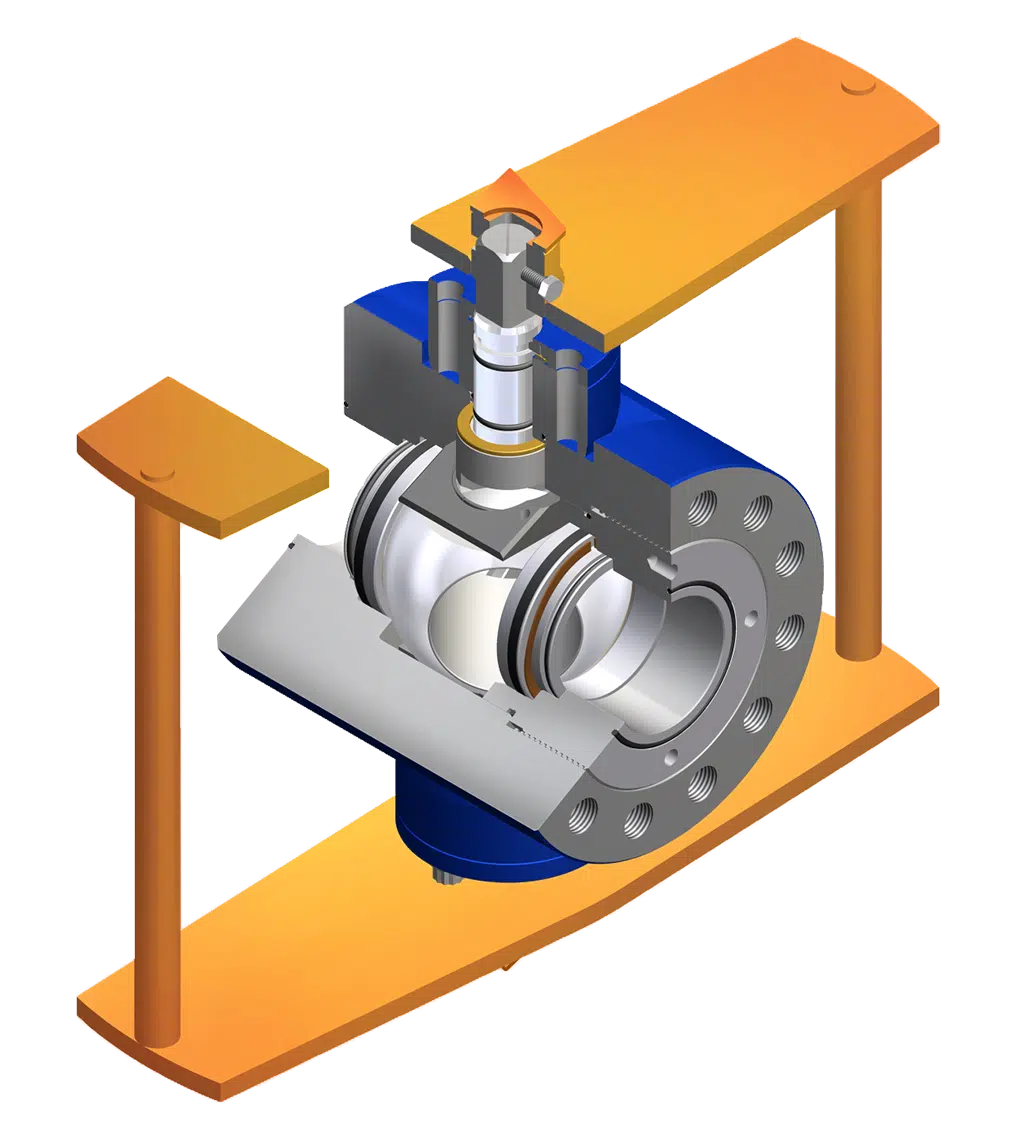

Compact Ball Valves are designed for high pressure isolation and offer considerable space and weight savings when compared to traditional ANSI and API class valves. CORTEC Compact Ball Valves are available in a range of bore sizes and working pressures.

CORTEC Compact Ball Valves are designed to provide reliable long-term service life and ease of maintenance. Unique side entry body and associated end connections make valve removal from the line easy, making repairs simple. Disassembly, in most cases, is accomplished without the need for special tools.

Design Features and Benefits

- Valve models are available in size range of 1/2” thru 24” nominal and are bore sized to API bore sizes, common piping schedules or project requirements. (Larger Nominal Sizes Available Upon Request)

- Pressures to 20,000 PSI

- Provide reliable long-term service life and are field friendly for serviceability.

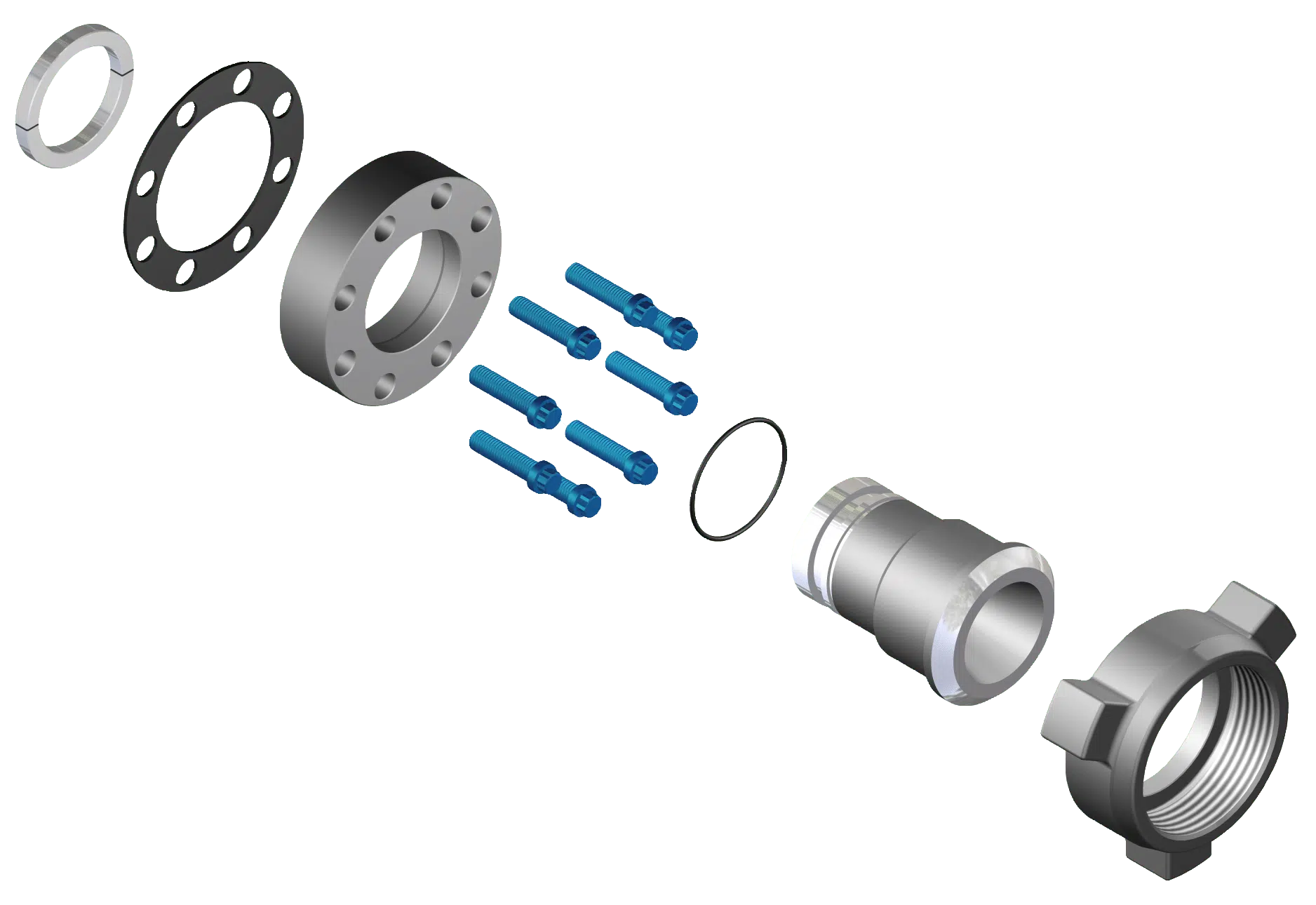

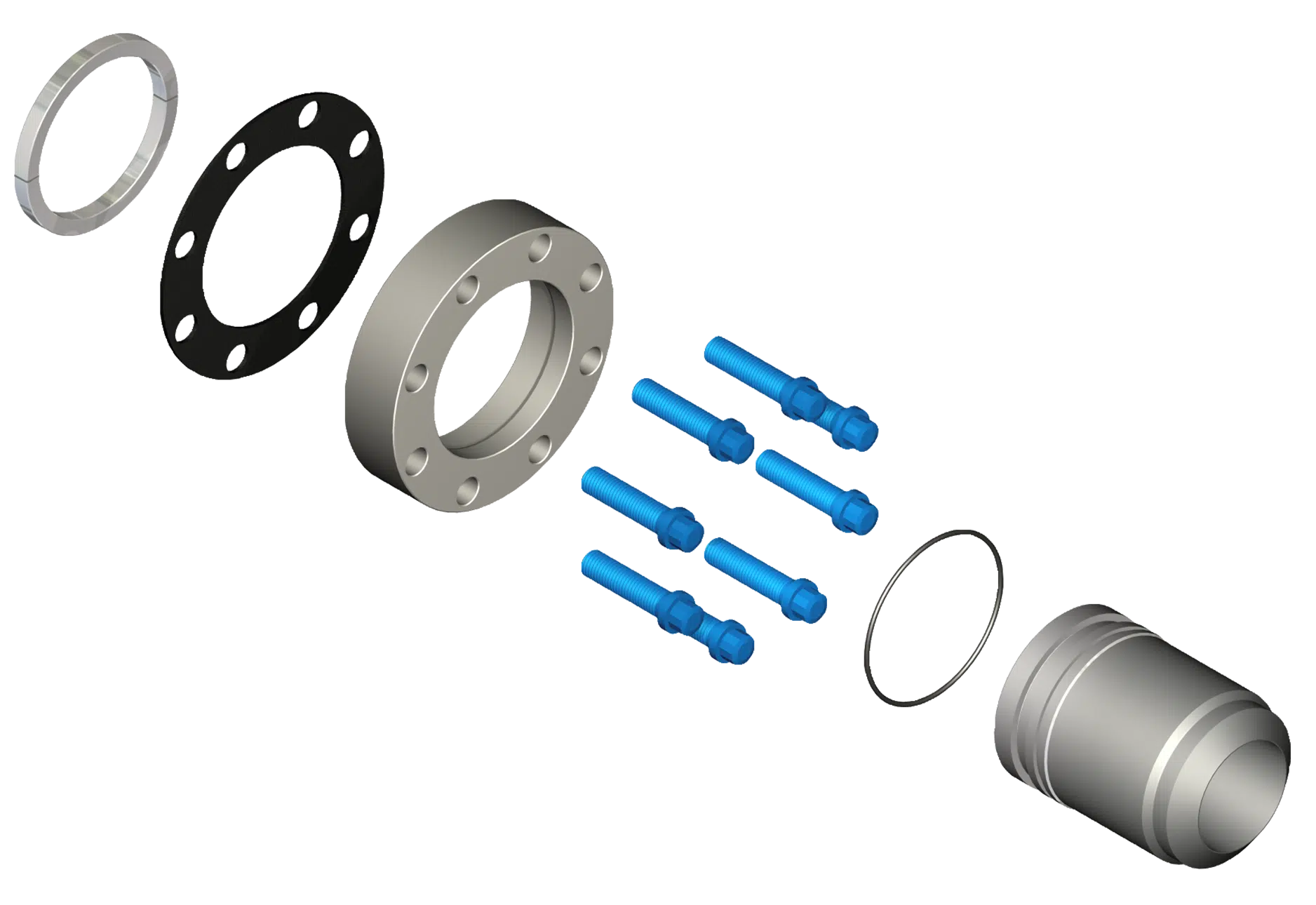

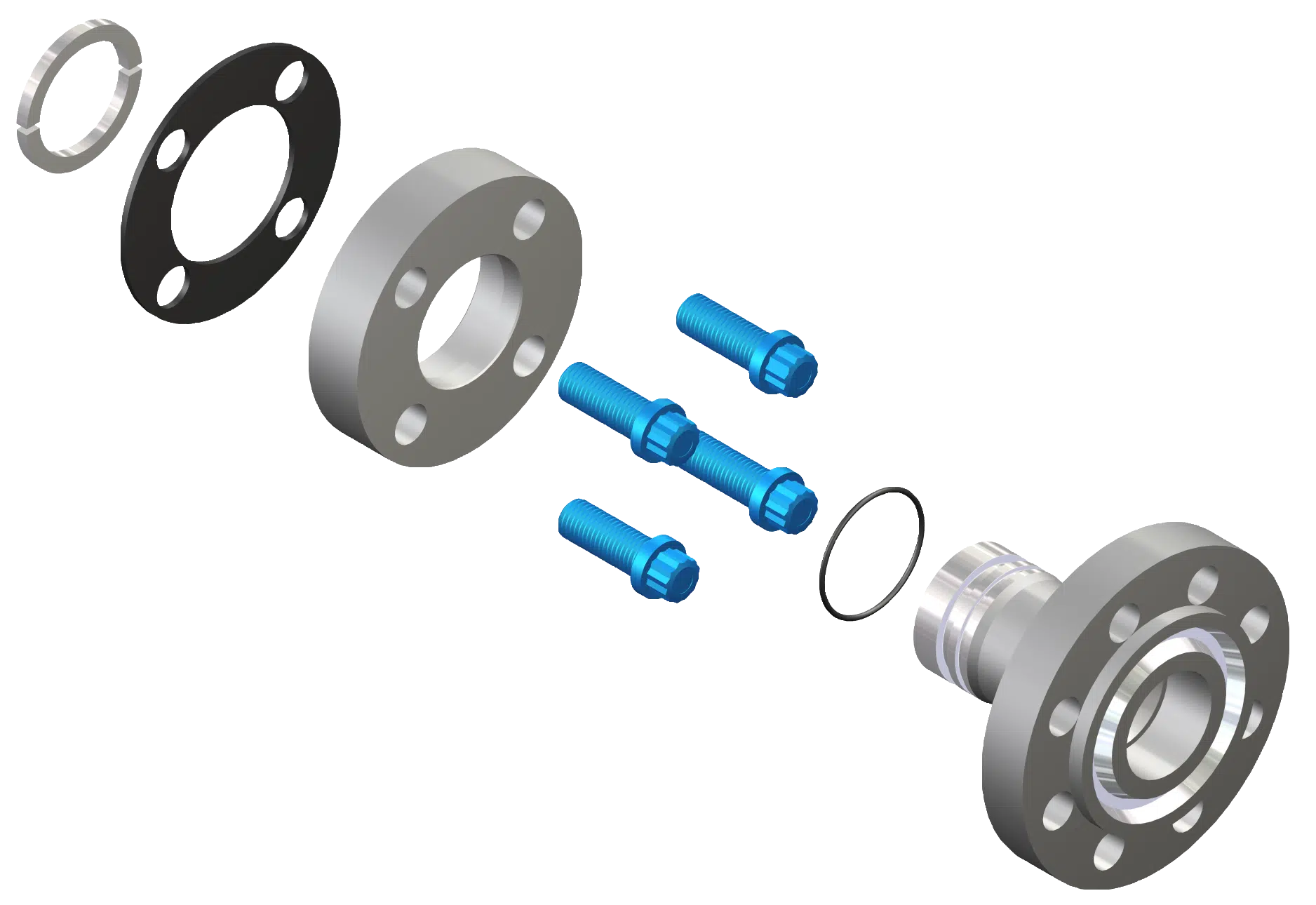

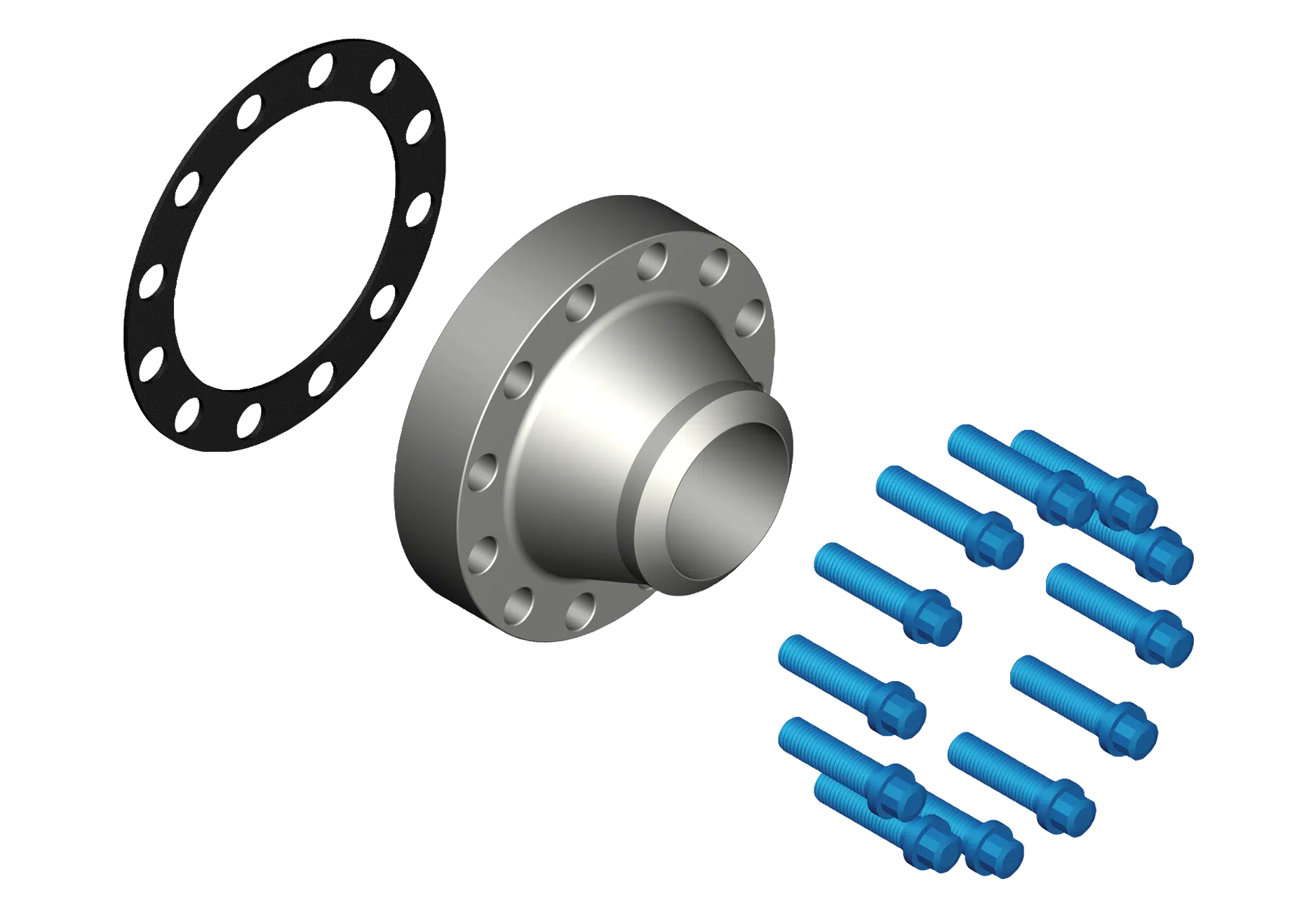

- Virtually any size and type of end connection is available (buttweld, threaded union, hub and crossovers to both ANSI and API flanges).

- Ball valves are offered with a variety of seating material options such as Celcon, PEEK or Tungsten Carbide metal-to-metal.

- Fire-safe designs have been independently qualified to API 6FA.

- Valve models can be ordered compliant to:

- API 6A with or without monogram

- API 6AV1 “Sand Slurry” (PSL levels 1, 2, 3, 3G, 4)

- API 6A PR2F

- API 6D

- NACE

- Third party certification available upon request

- Ball valves are a quarter turn design and can be supplied as either manual lever / gear or actuated.

Traditional vs Compact Ball Valve Comparison

Compact Ball Valve Models

Trunnion

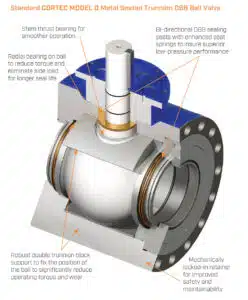

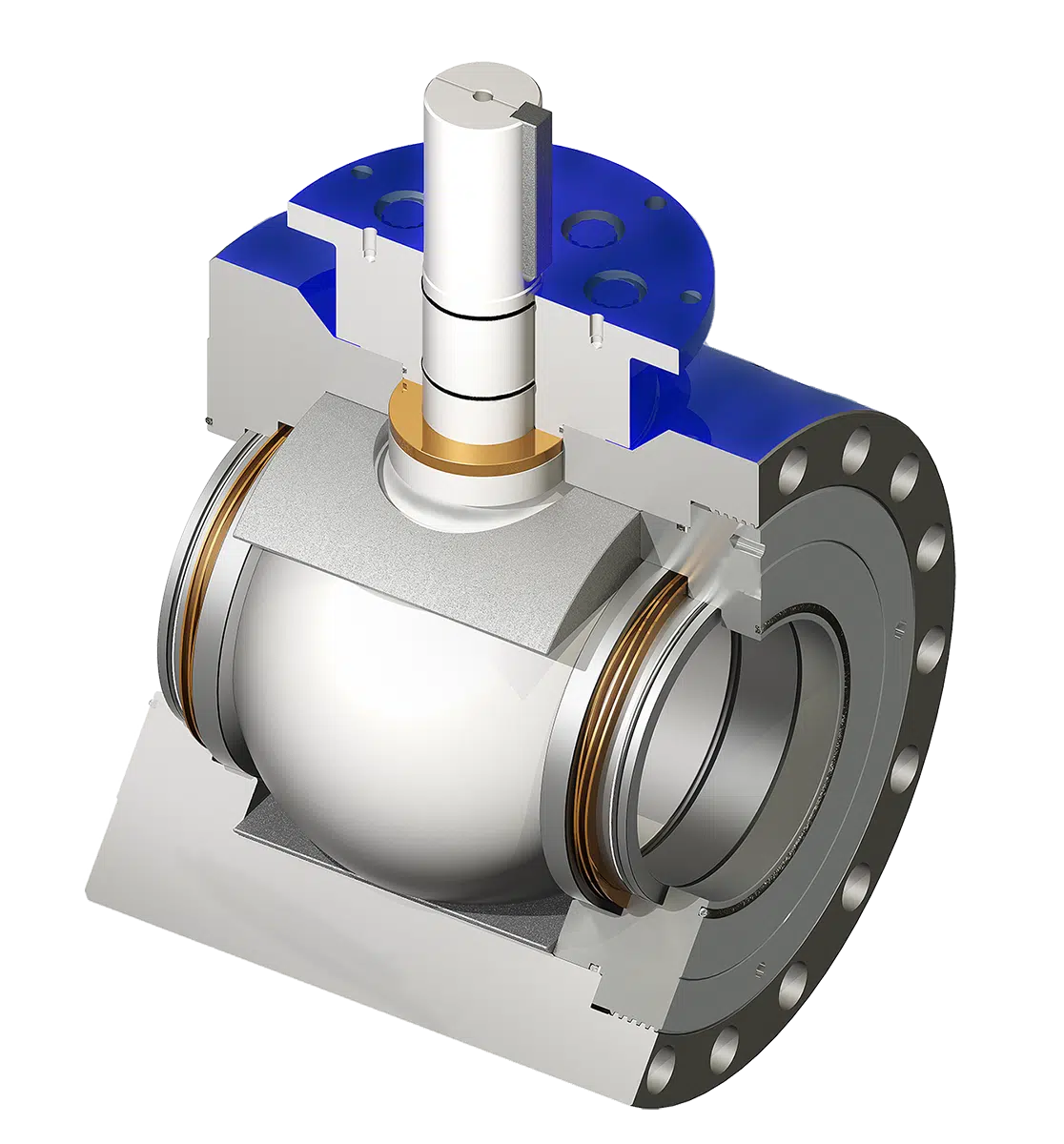

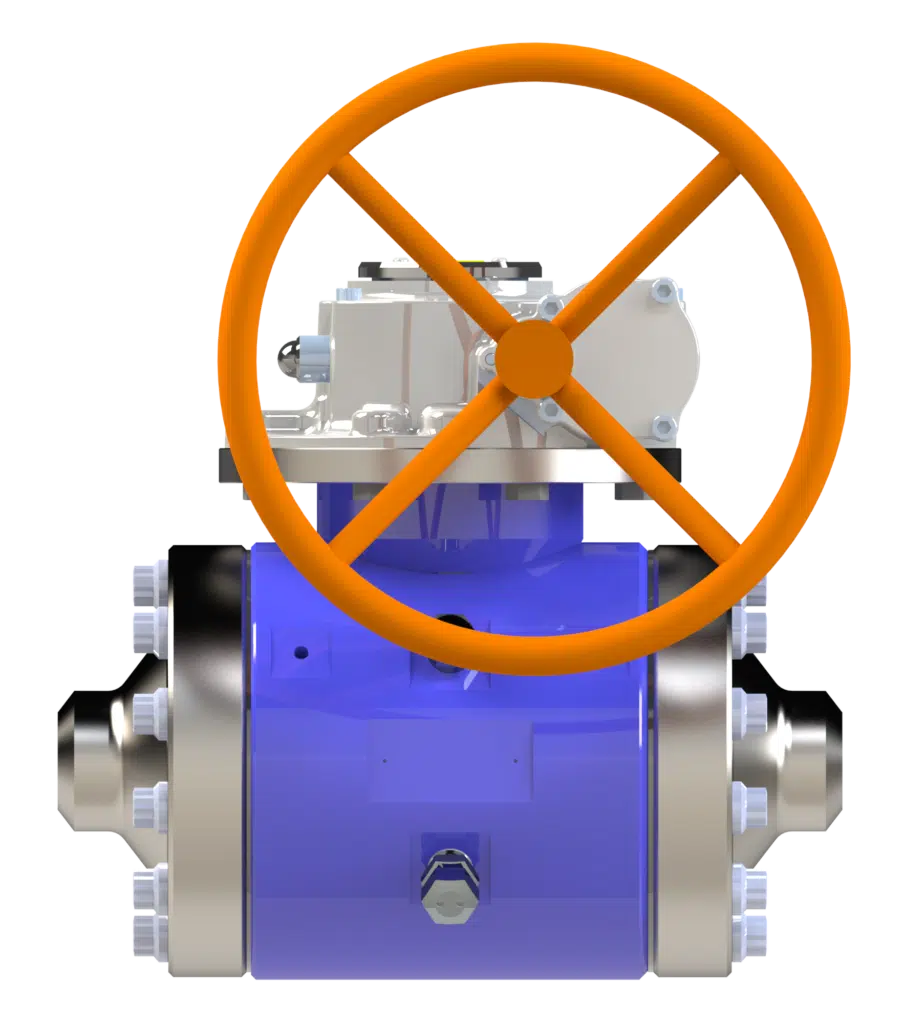

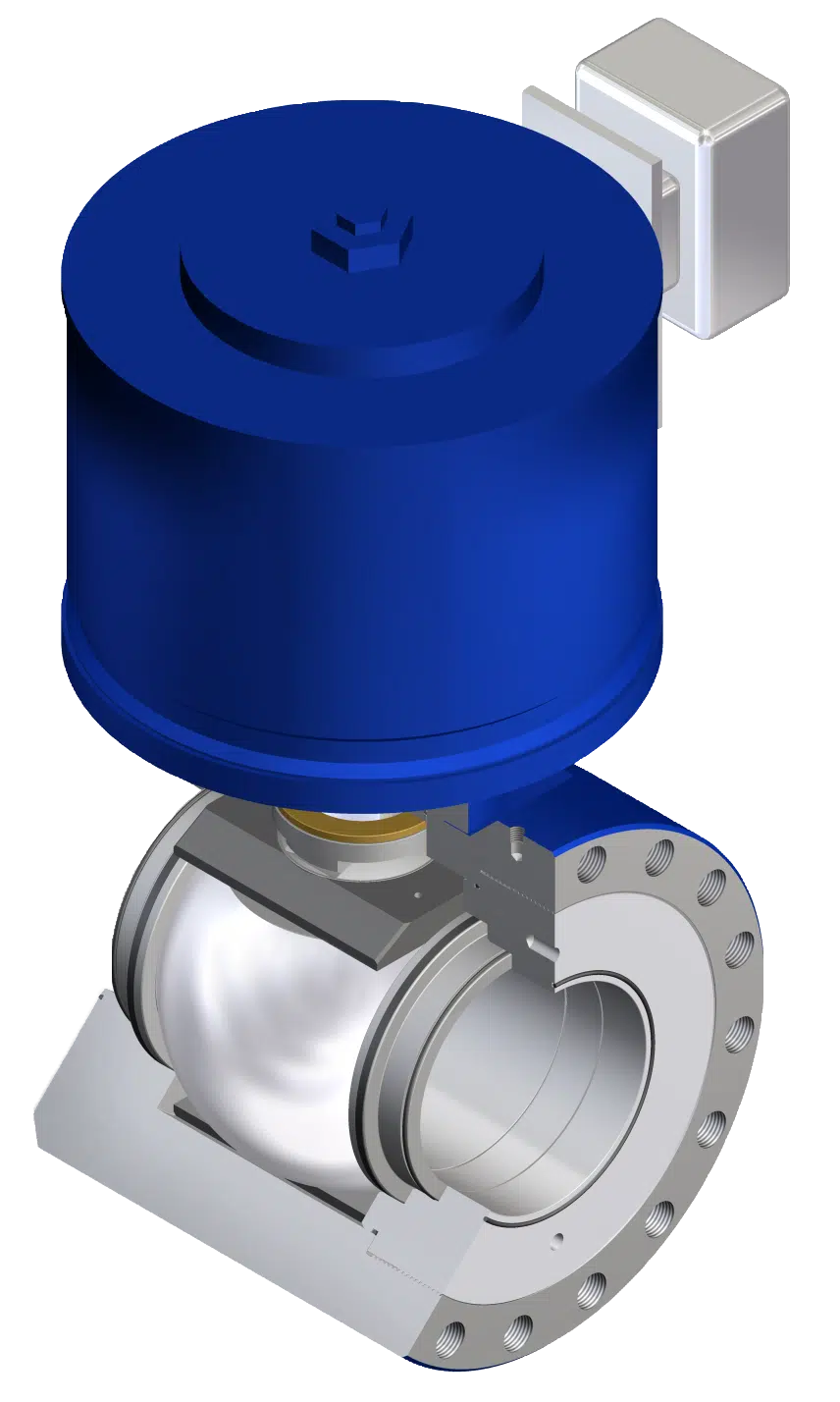

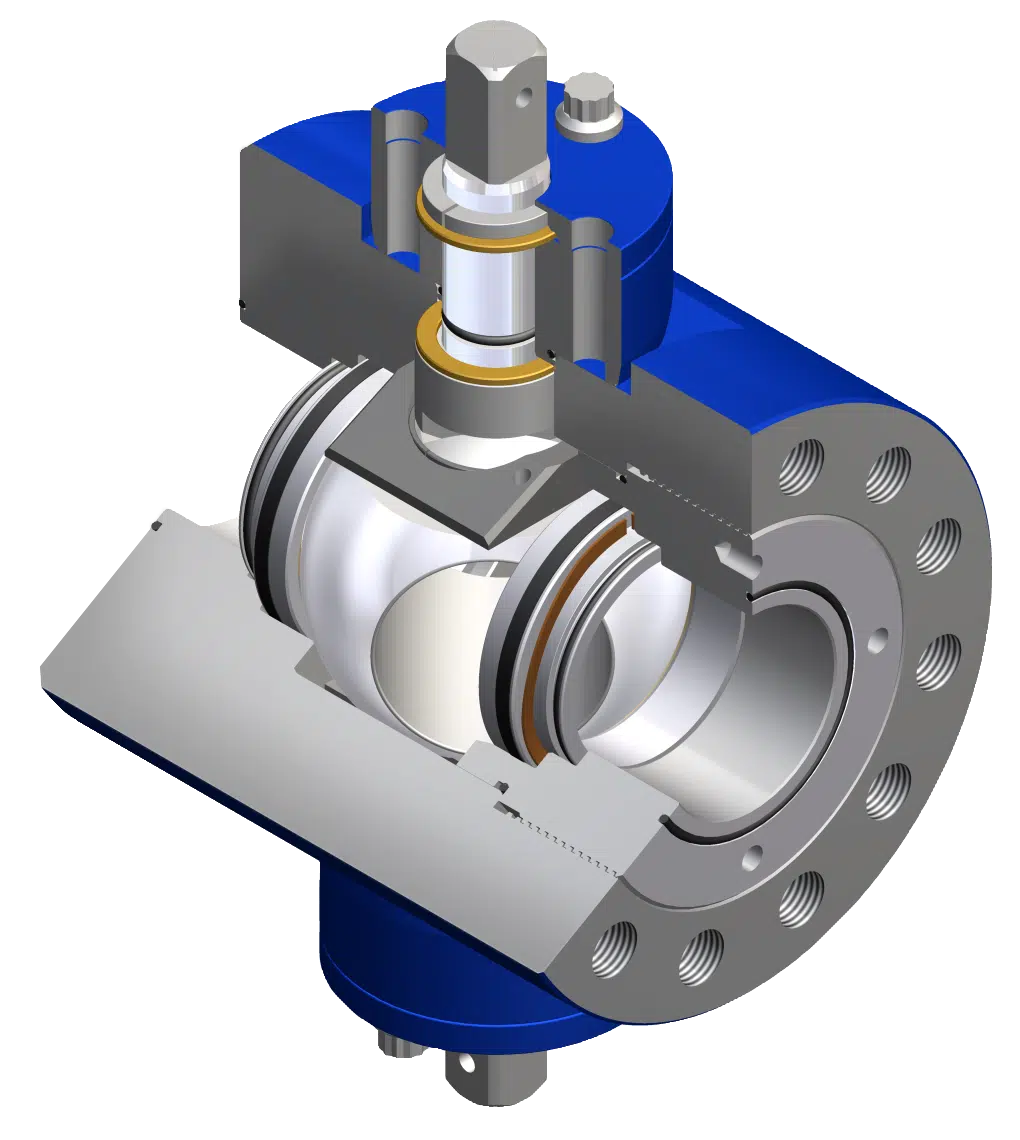

CORTEC Model “D” Compact Trunnion Ball Valve

The CORTEC Model “D” Series Ball Valve is a double trunnion design. The ball is held firmly in place by two large trunnion blocks, allowing only rotational movement. With the ball always perfectly aligned, independent spring-loaded upstream and downstream seats are always in contact with the ball, which provides an effective tight seal even at very low pressures. The Double Trunnion design permits ease of operation and significantly reduces torque. Our use of robust double trunnions and spring-loaded seats affords the most reliable configuration. The “D” Series Ball Valve can be supplied with polymeric or metal seats. Every valve is DBB (Double Block & Bleed) and is equipped with stainless steel vent fitting that allows the body cavity to be easily bled.

Design Features and Benefits

- Size ranging from 1/2” to 24” (Larger Nominal Sizes Available Upon Request)

- Pressures to 20,000 PSI

- Polymeric or Tungsten Carbide metal-to-metal sealing

- Designs featuring primary lip seal technology available upon request

- Subsea models available

- API 6AV1 “Sand Slurry” Certified design option

- API 6FA Certified fire-tested designs

- Customizable to application requirements

- Valve bore can be sized to match pipe bore

- Multiple end connections available

- Manual lever / gear or actuated

Floating

CORTEC Model “B/BC” Compact Floating Ball Valve

The CORTEC Model “B/BC” Series Ball Valve is a floating ball and dual floating seat design. The floating ball is preloaded between the seats during assembly and moves incrementally tighter against the seats as line pressure increases. It will provide a reliable positive shutoff in either flow direction. The removable bonnet design allows for field replacement of the stem seal without removing the valve from the pipe. A stainless steel body injection fitting is a standard feature for providing routine lubrication of the body cavity, which reduces the operating torque and extends the service life. This injection fitting can also be used for the injection of emergency sealant. The “B/BC” class valve is also available with throttle balls for throttling under high differential pressures.

Design Features and Benefits

- Sizes ranging from 1” thru 3”

- Pressures to 15,000 PSI

- Polymeric seating material options

- Subsea models available

- API 6FA Certified fire-tested designs

- Customizable to application requirements

- Valve bore can be sized to match pipe bore

- Multiple end connections available

- Manual lever / gear or actuated

CORTEC is setting industry standards with our reliable critical service valve designs. CORTEC Critical Service Valves are engineered and manufactured to offer maximum safety and confidence in extreme applications where substantial amounts of abrasives, high pressures, and severe temperatures are present, and all in a lightweight, space-saving compact valve design.

CORTEC MODEL D COMPACT BALL VALVE

The CORTEC MODEL D Compact Ball Valve series is designed as a standard metal seated trunnion ball valve which is the ideal solution for applications involving abrasives, high temperature, or both. Tungsten carbide-coated ball and seats provide the hard surfaces required to resist damage from abrasives and minimize wear while meeting API 6A zero leakage criteria. Stem and ball designs are robustly designed to accommodate the higher torque requirements of these metal seated valves. The CORTEC MODEL D series is designed with a double trunnion block support to maintain perfect alignment of the ball even at high pressures and temperatures.

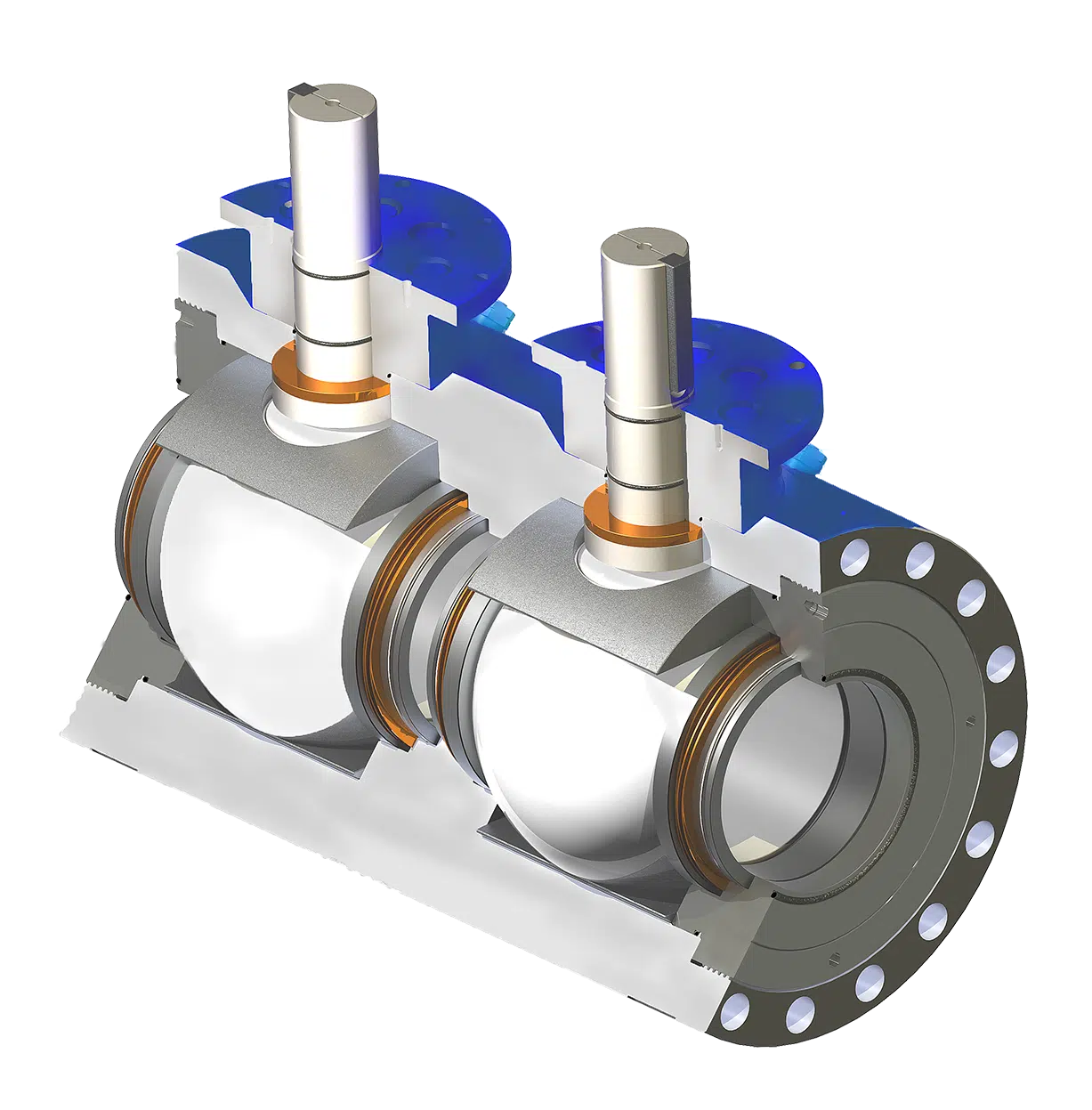

CORTEC MODEL D DOUBLE BLOCK & BLEED (DBB)

The CORTEC MODEL D DBB design featuring spring-loaded independent upstream and downstream seats capable of providing bi-directional zero leakage from very low pressures up to 20,000 PSI.

FEATURES

- Sizes ranging from 1/2” to 24”

(Larger Nominal Sizes Available Upon Request)

- Pressures up to 20,000 PSI

- Tungsten Carbide metal-to-metal seat to ball sealing

- Valve bores can be sized to match pipe bore

- Valve models can be ordered compliant to:

- API 6A with or without monogram

- API 6AV1 “Sand Slurry” certified

- Certified BSDV (Boarding Shutdown Valve)

- API 6FA and API 607 fire-test certified

- API 6D

- NACE

- Third party certification available upon request

- Multiple end connections available

- Customizable to application requirements

- Manual lever/gear or power actuated

- API 6A PR2F

- 30 CFR 250 Subpart H (BSEE/SPPE) tested designs

- PSL levels 1, 2, 3, 3G, 4

DBB Diagram

Click to enlarge

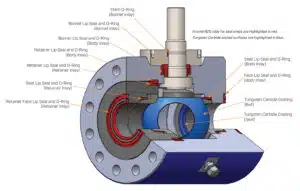

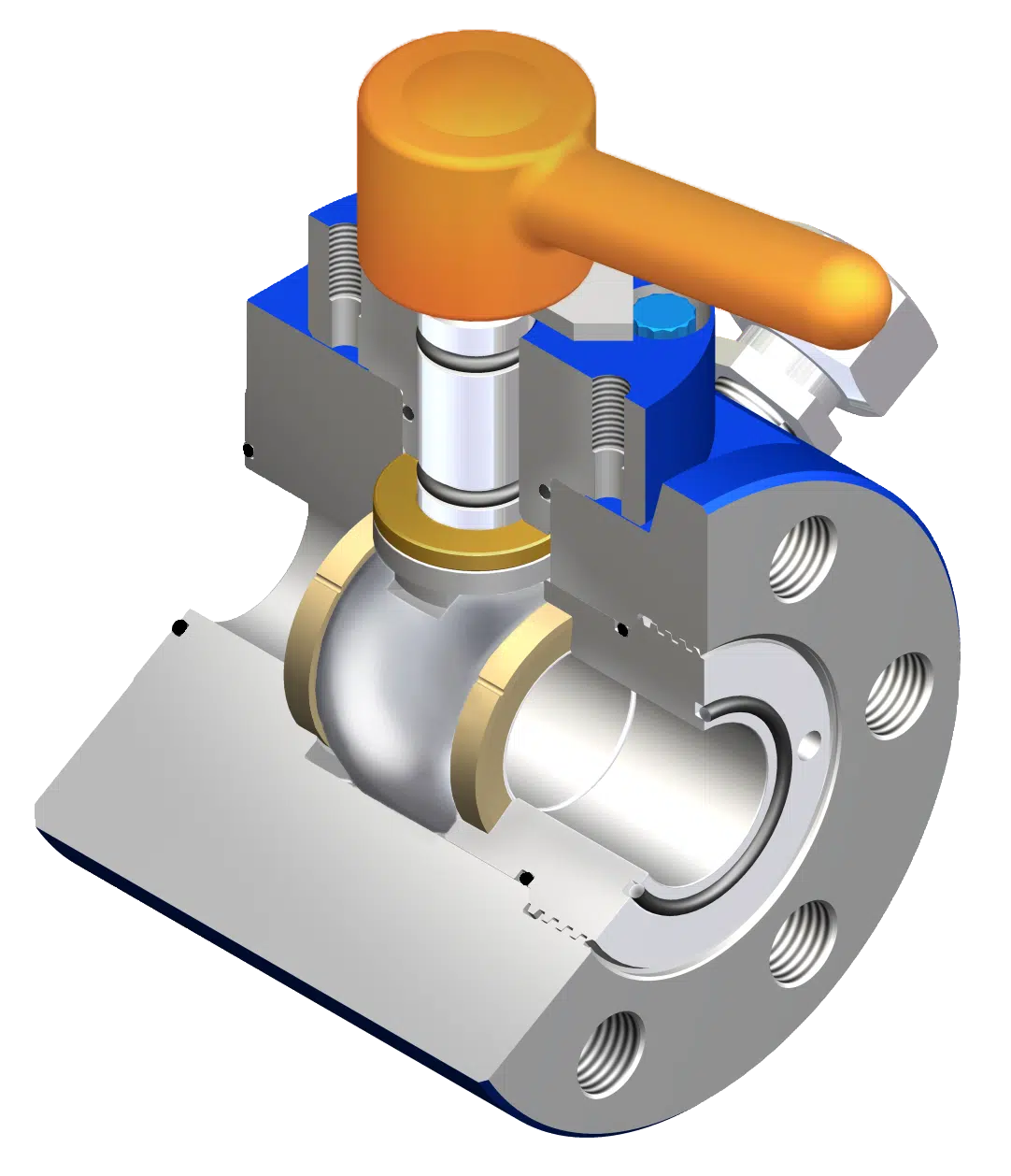

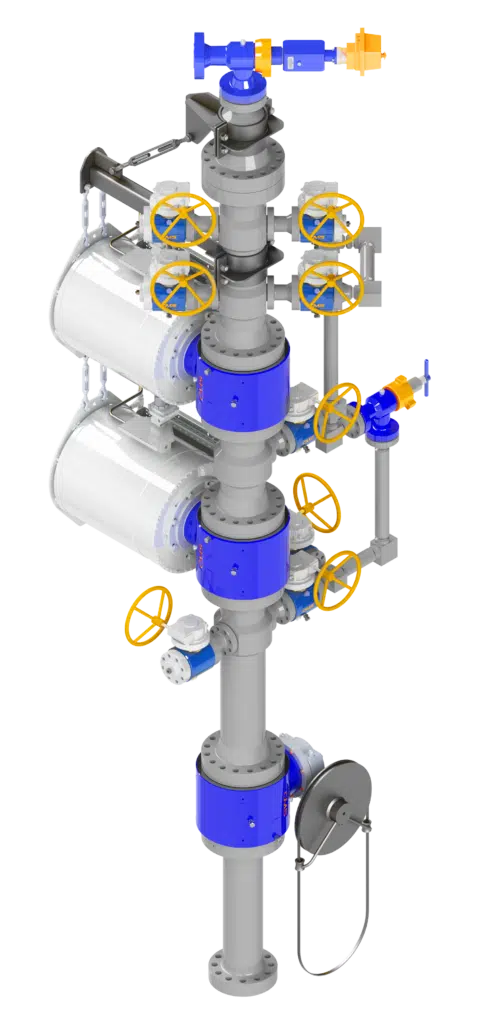

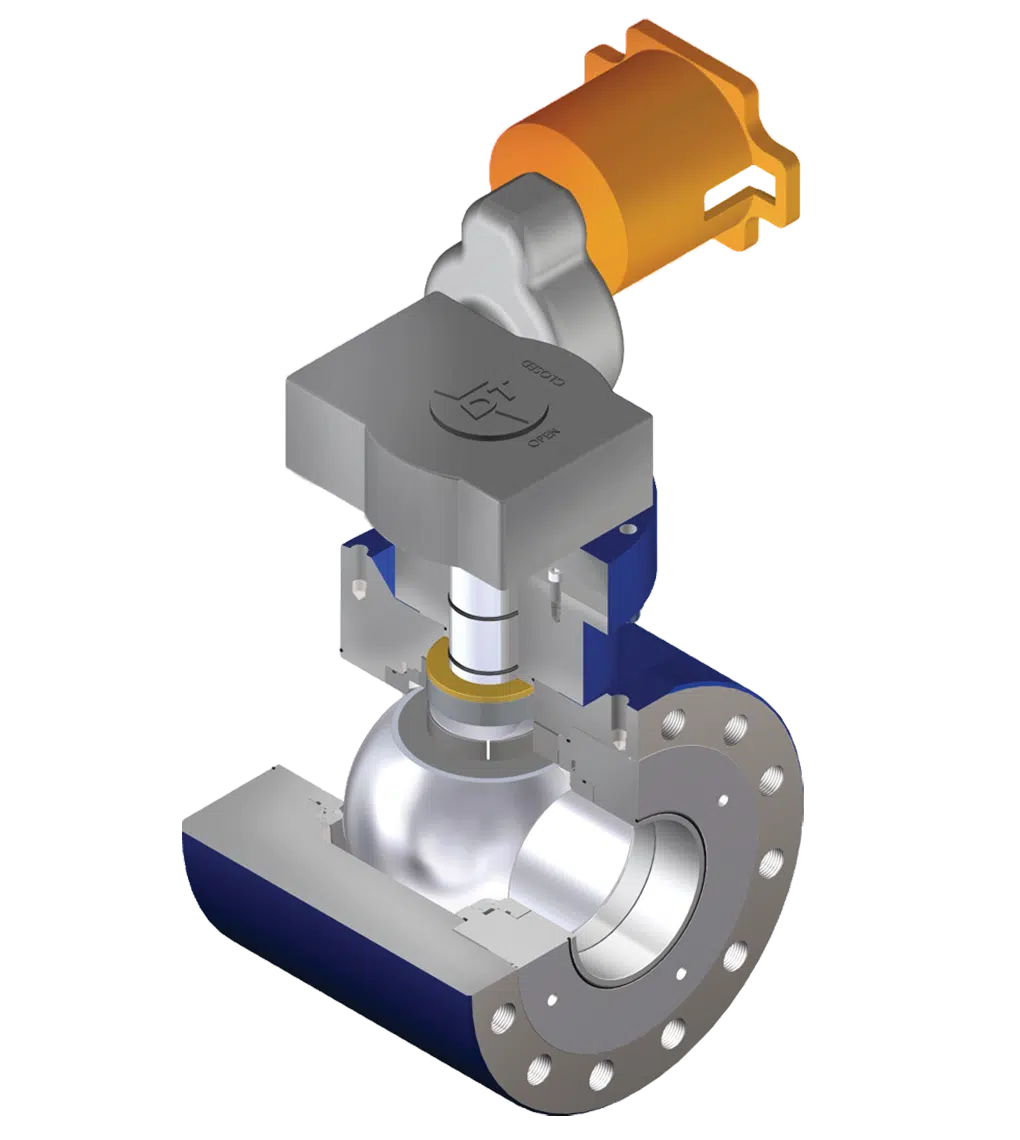

CORTEC MODEL LD

IDEAL USES: Boarding Shutdown Valves (BSDV), Surface Safety Valves (SSV) and Underwater Safety Valves (USV)

For valves used in critical applications such as BSDV, GLSDV, or SSV, CORTEC developed the MODEL LD Compact Ball Valve series. This series of metal seated valves are designed to function in the most extreme circumstances, including temperature, pressure, flow rates with abrasives and other adverse conditions.

The CORTEC MODEL LDs are manufactured using materials and sealing elements that are designed to last for the life of the well. For this long-term operability, attention is given to all sealing areas, not just the bore sealing mechanism (seat-to-ball seal). This series uses specially designed spring energized lip seals on all primary sealing elements. Special attention is given to the design of these lip seals to ensure reliable sealing from very low up to full-rated working pressure, and additionally, the materials used in sealing gland areas are selected for continued dependability. CORTEC’s designs include provisions for Inconel 625 overlays, in accordance with API 6A, to greatly improve reliability and longevity in all areas of the valve.

Model LD Diagram

Click to enlarge

CORTEC is setting industry standards with our robust BSDV compact ball valve designs. CORTEC BSDV valves are designed and tested to meet the requirements of 30 CFR 250, Subpart H which is required by BSEE for riser applications in the US Gulf of Mexico. All BSDV’s are manufactured under an API Q1 quality system, and shipped with documentation that certifies API 6A and API 6AV1 Class II (Sand Slurry Tested) compliance as well as API 6FA fire rated.

For valves used in critical applications such as BSDVs (Boarding Shutdown Valves), CORTEC’s metal seated valves are designed to function in the most extreme conditions to which they may be exposed. This includes temperature, pressure, flow rates with abrasives and other adverse conditions. BSDVs are manufactured using materials and sealing elements that are designed to last for the life of the well. In addition, CORTEC BSDV and GLSDV assemblies are PR2F rated and tested at both min and max temps in accordance with API 6A requirements.

For long term operability, attention is given to all sealing areas, not just the bore sealing mechanism (seat to ball seal). For this reason, CORTEC has developed the “LD” Series Ball Valve. This valve uses specially designed spring energized lip seals in all primary sealing elements.

Special attention has been given to the design of these lip seals to ensure reliable sealing from very low pressures to full rated working pressure. Additionally, the materials used in sealing gland areas are selected for long term reliable sealing.

CORTEC’s designs include provisions for Inconel 625 overlays, in accordance with API 6A, to greatly improve sealing reliability and longevity in all areas of the valve. Please consult with your CORTEC representative for additional information.

Designs API 6A 21st Compliant To:

- 6AV1

- PR2F

- PSL 1, 2, 3, 3G, 4

Designs ACF Compliant To:

- 6A

- 6AV1

- FR

- Q1

CORTEC designs and manufactures BSDV packages in accordance with API 6A, API 6 AV1 & API 6FA requirements and specifically tailored to customer specifications. Allowing CORTEC to engineer and design the turnkey piping assembly ensures accurate fit up in the field while maximizing the potential for weight and space savings.

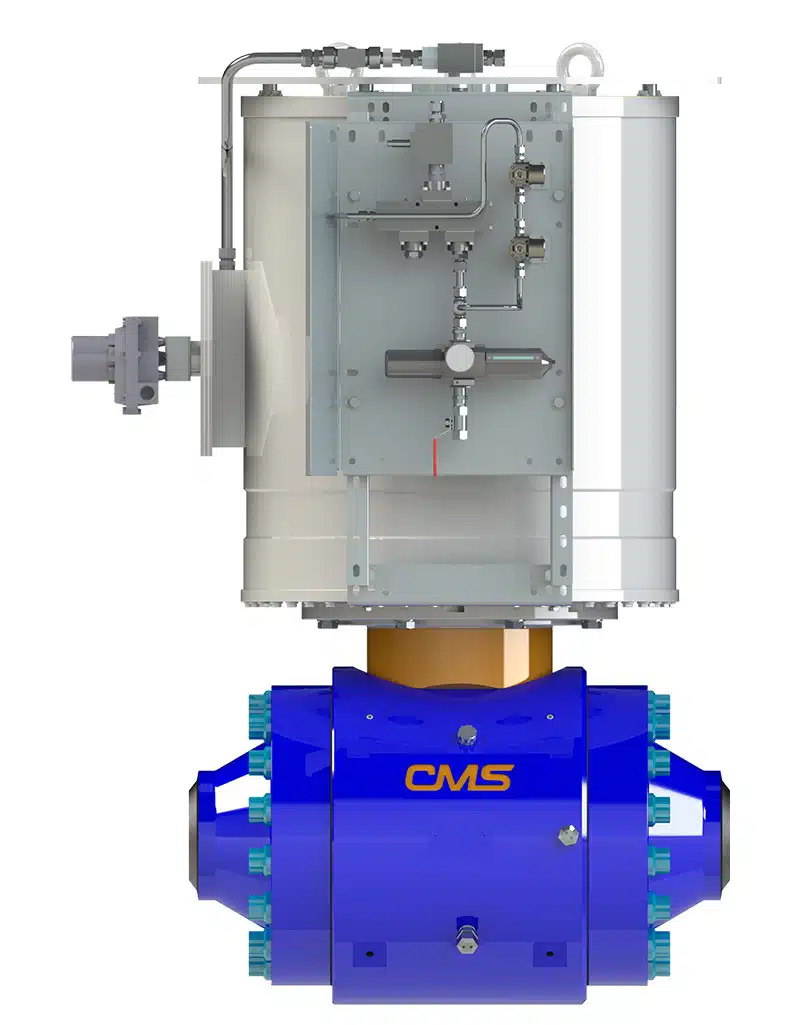

CORTEC 5-1/8” Bore 15,000 PSI metal seated BSDV with compact style fail close actuator

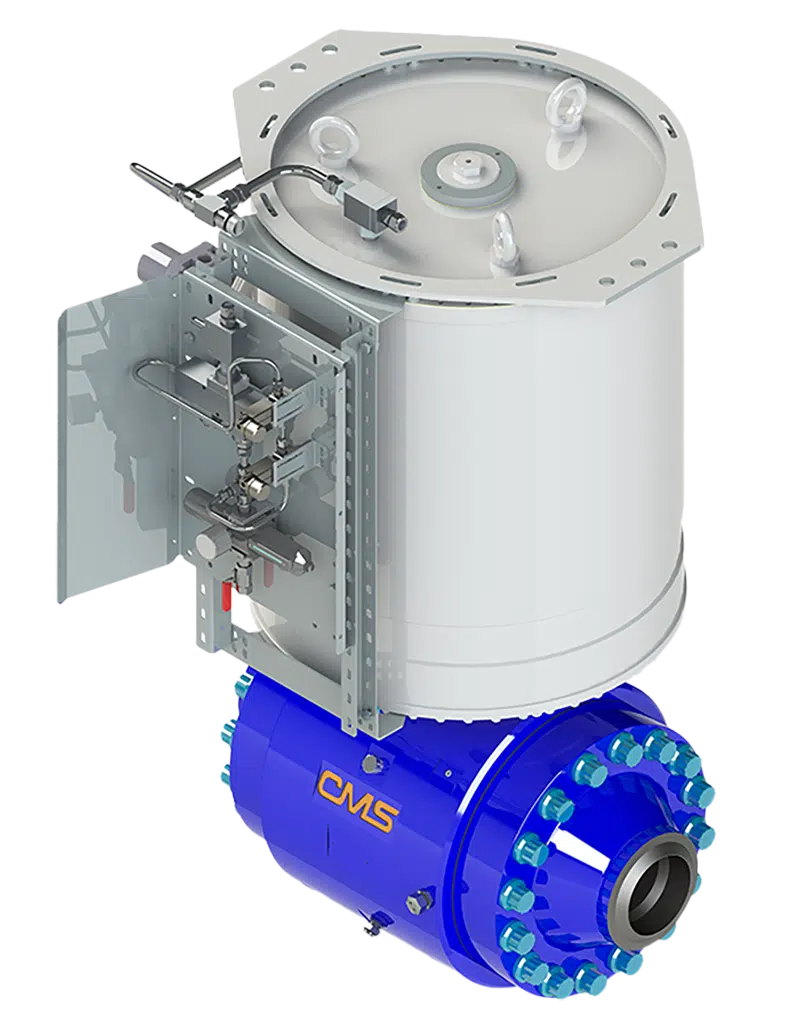

Engineered for High-integrity Sealing

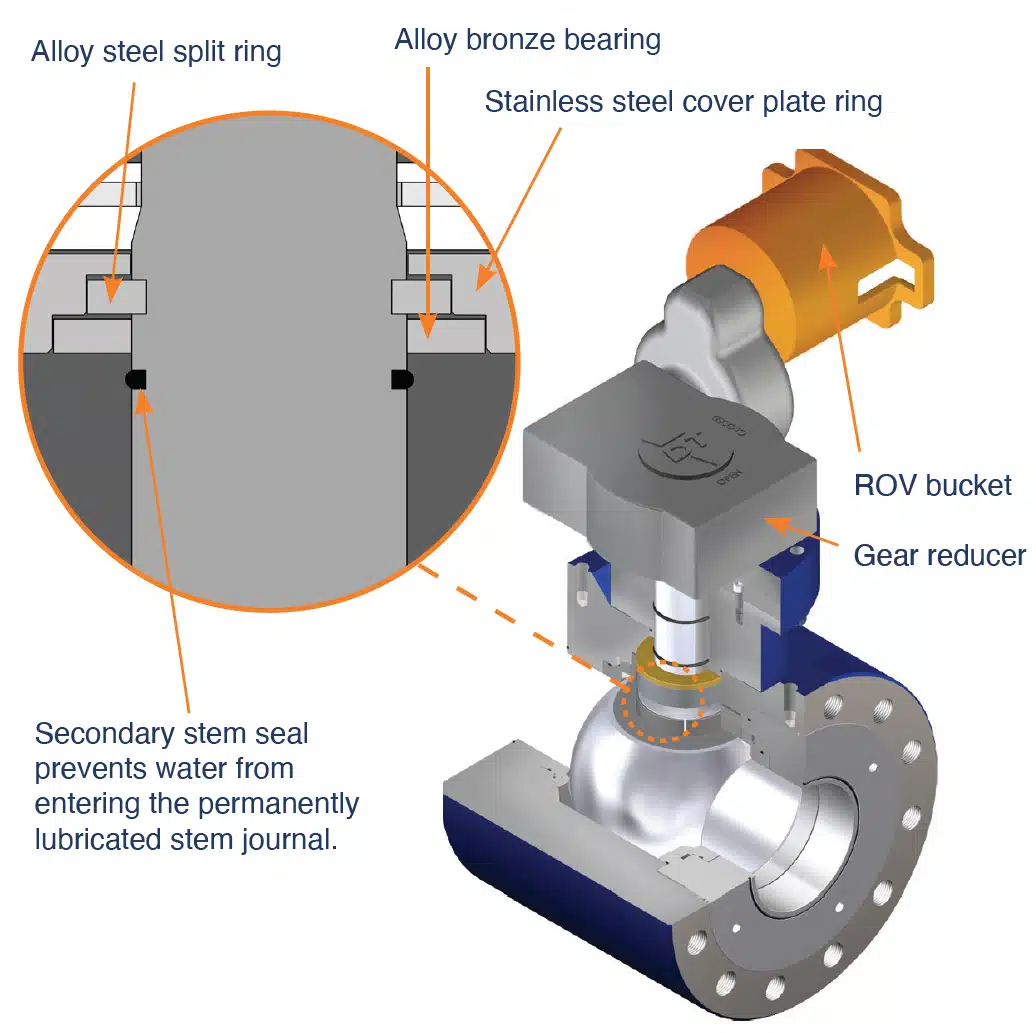

The CORTEC Subsea Ball Valve is engineered for high-integrity sealing and trouble-free operation in a wide range of harsh subsea service environments.

Features and Benefits

- Compact body design reduces leak paths with greater material integrity.

- Readily operable with industry standard ROV’s via a standard API-17D interface or configured with an easy grab handle to show valve position.

- Optional double stem.

- Split ring thrust collar isolates the hydraulic stem thrust, preventing the stem from being displaced in the ball.

- Hyperbaric sealing employed as needed to prevent water ingress.

- If cathodic protection is required, electrical continuity between valve components can be provided.

- Offered as either floating or trunnion design.

- Sizes range from 1″ through 12″

- ANSI CL1500 to 15,000 psi working pressure

- Available in trunnion or floating design

- Water depths to 10,000 feet

- Bore sized to common piping schedules

- Available in most any size and type end connection

CORTEC offers subsea valves for a variety of applications:

CORTEC offers complete mounting versatility with these end connections:

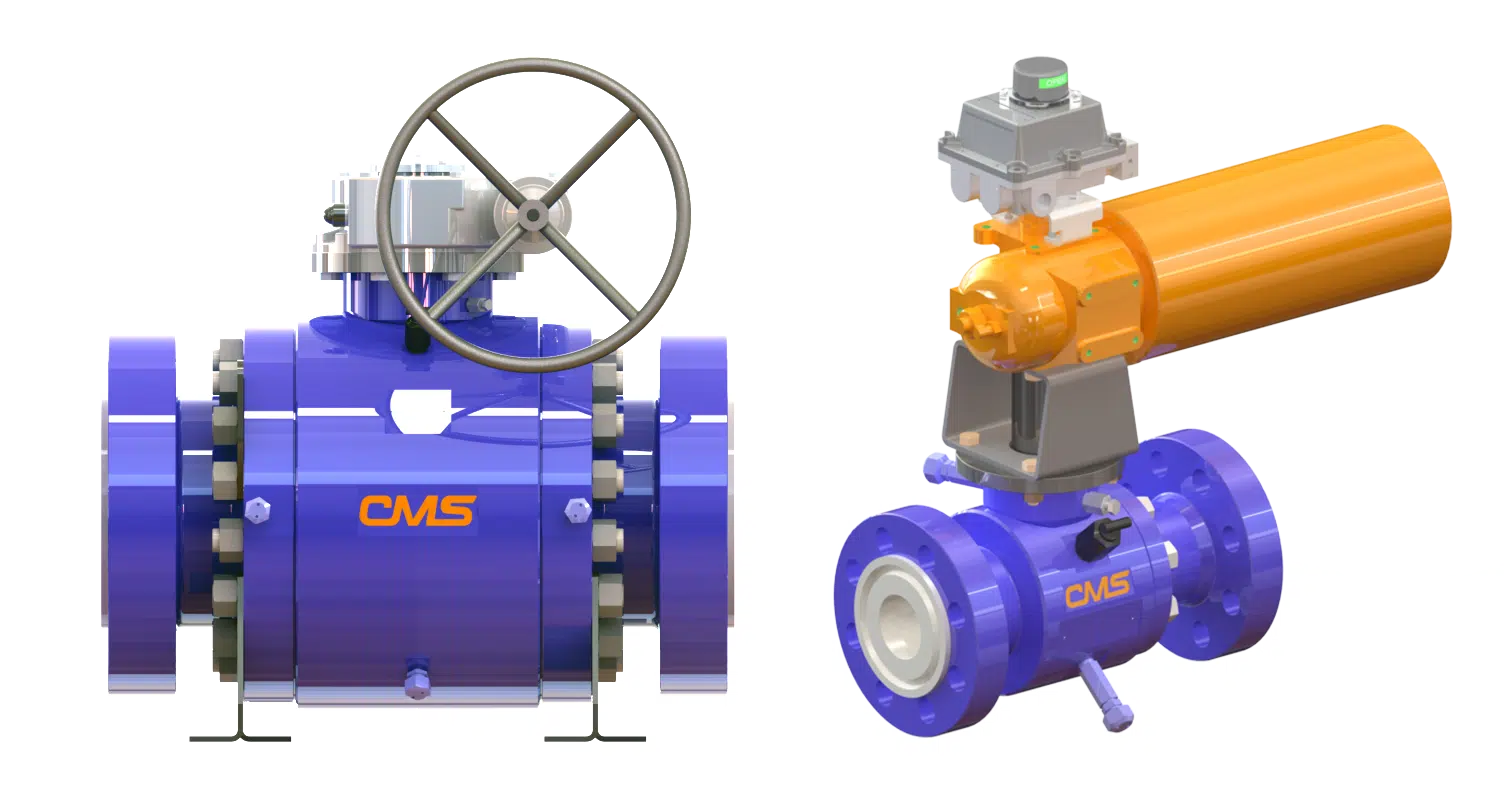

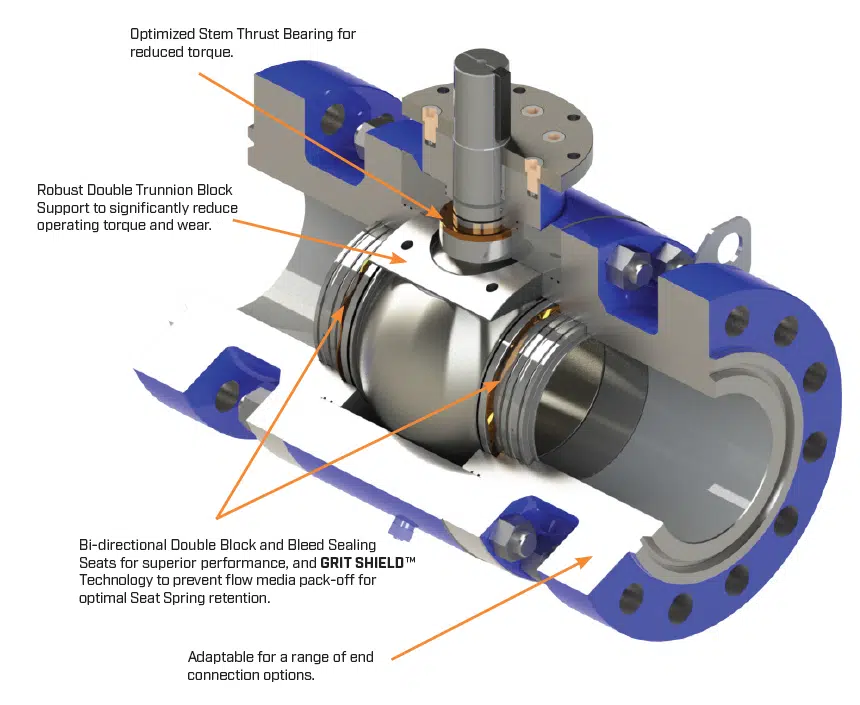

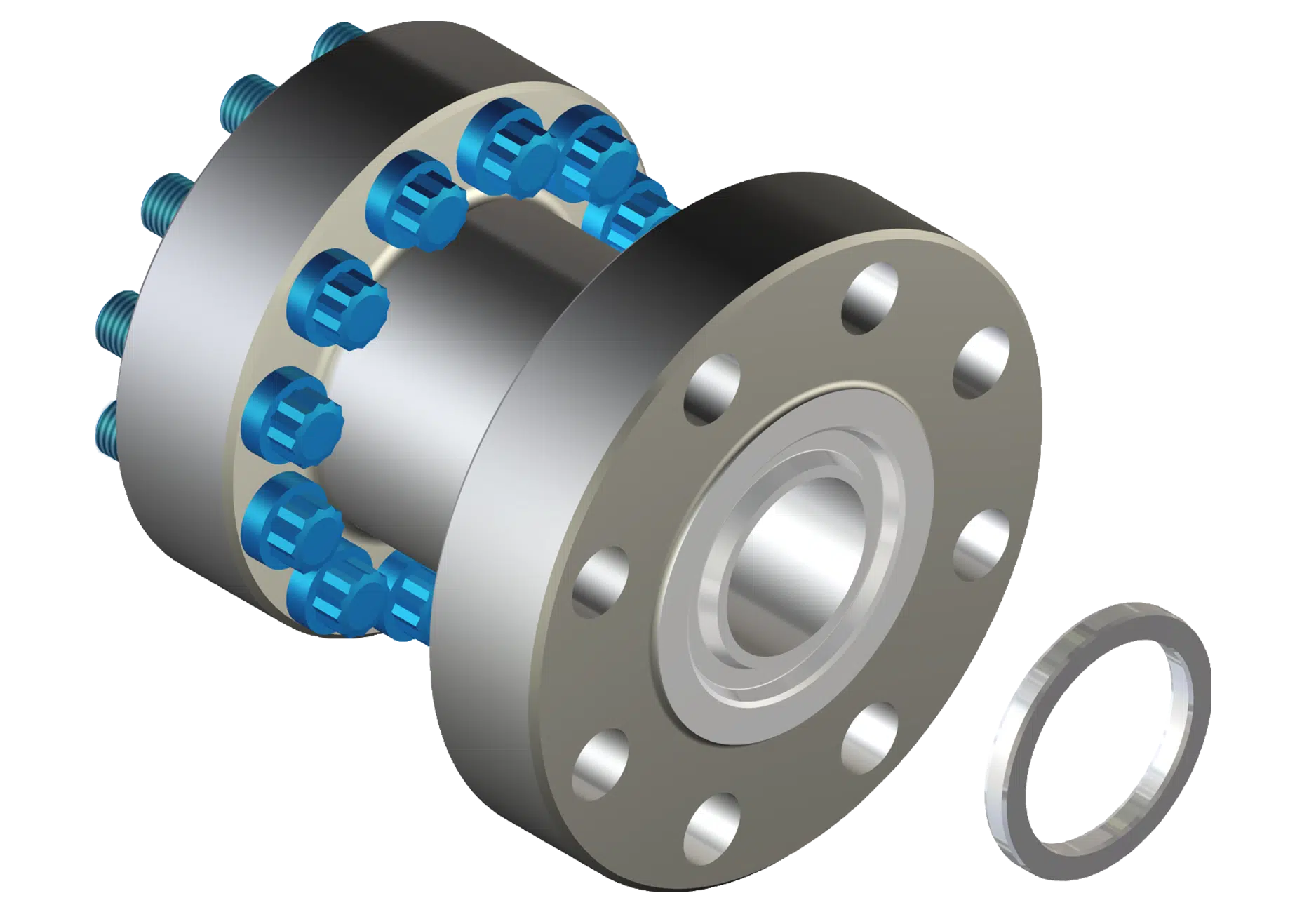

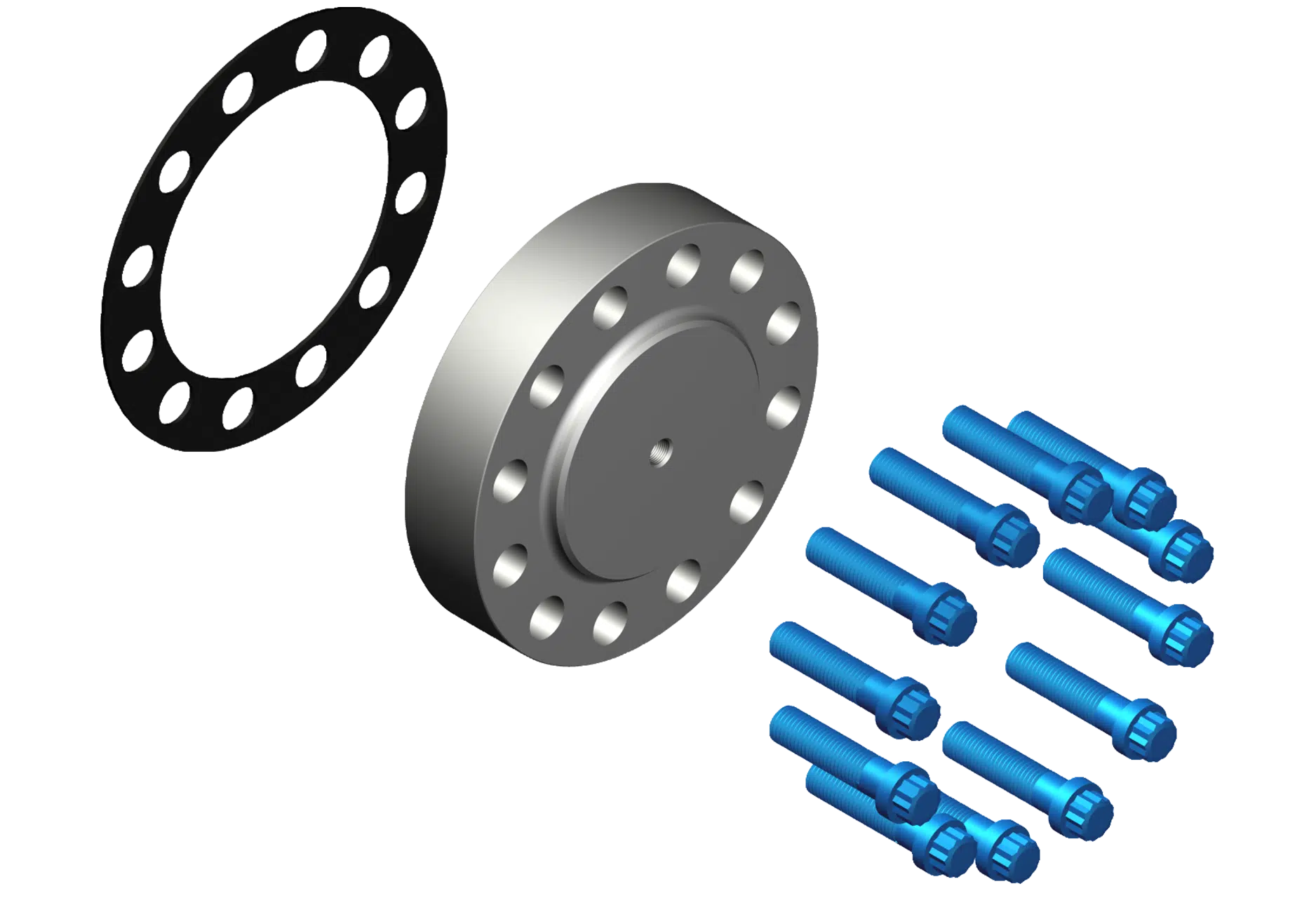

Conventional Flanged-End Valves

In addition to industry-leading compact critical service API 6A valve products within the upstream oil and gas market, CORTEC offers an expanded valve range that is well-suited to various energy industry applications. We design and manufacture valve products under API 6A and 6D licenses. CORTEC provides a complete line of conventional flanged end API 6A and 6D ball valves, which benefit from our high-pressure and critical service application background. These models are configured in a range of various sizes, materials, and actuation options. They include CORTEC’s advanced Metal-Seated technology, which sets standards for high-integrity performance, and GRIT SHIELD™ technology, which prevents seat spring pack-off by flow media.

Our family of API 6A/6D ball valves can be tailored to suit a wide range of industry applications and requirements.

All CORTEC products must pass rigorous testing prior to use in the field. These validation efforts include API 6A Annex F and API 6AV1 sand slurry certifications on most of our ball valve models. This standard provides the level of safety, integrity, and performance that our customers have come to expect of our brand. Our adaptable manufacturing processes, in combination with our hands-on design and engineering experience, assure the end user a solution tailored to their preferences without compromising quality, value, and delivery.